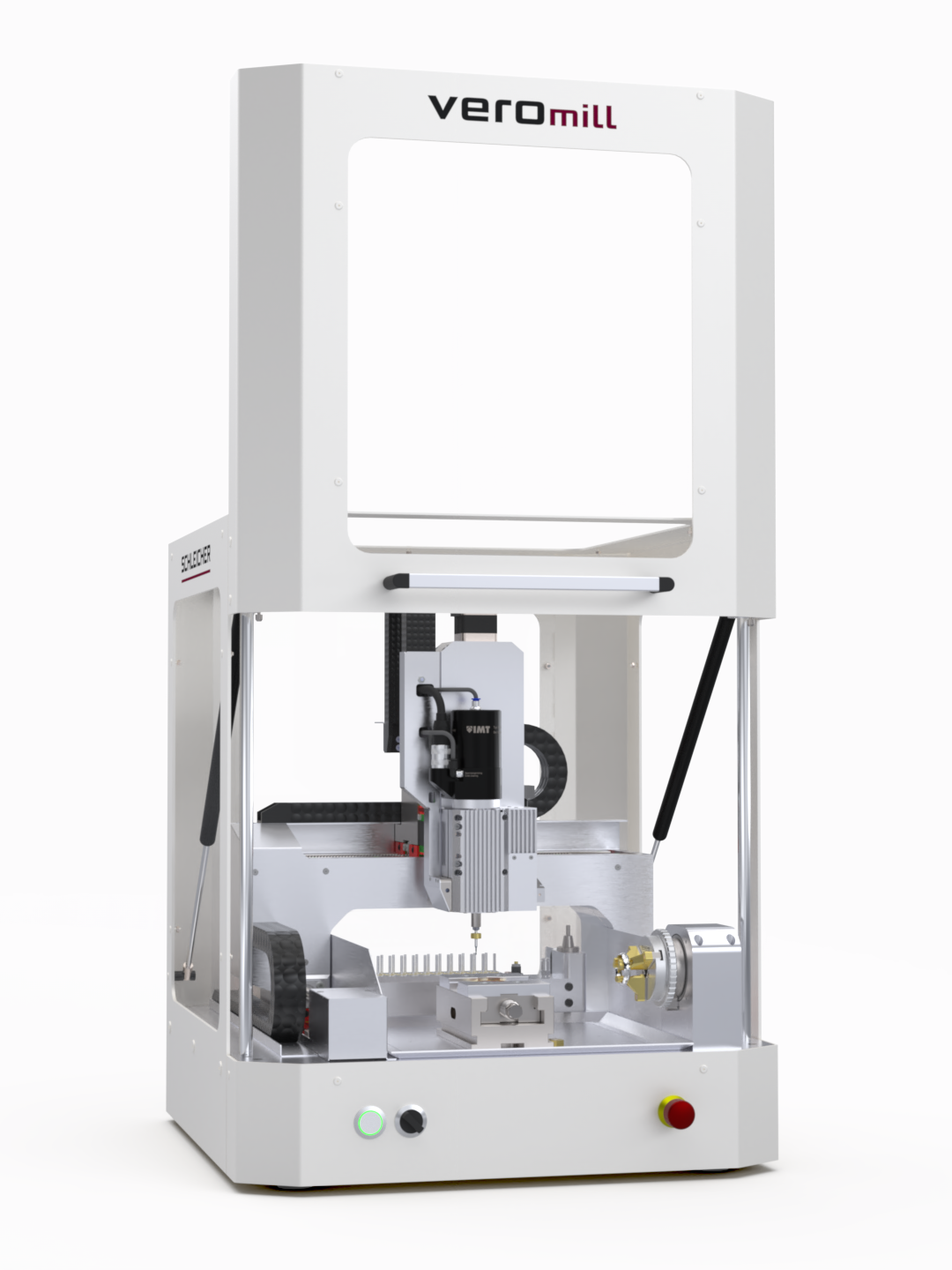

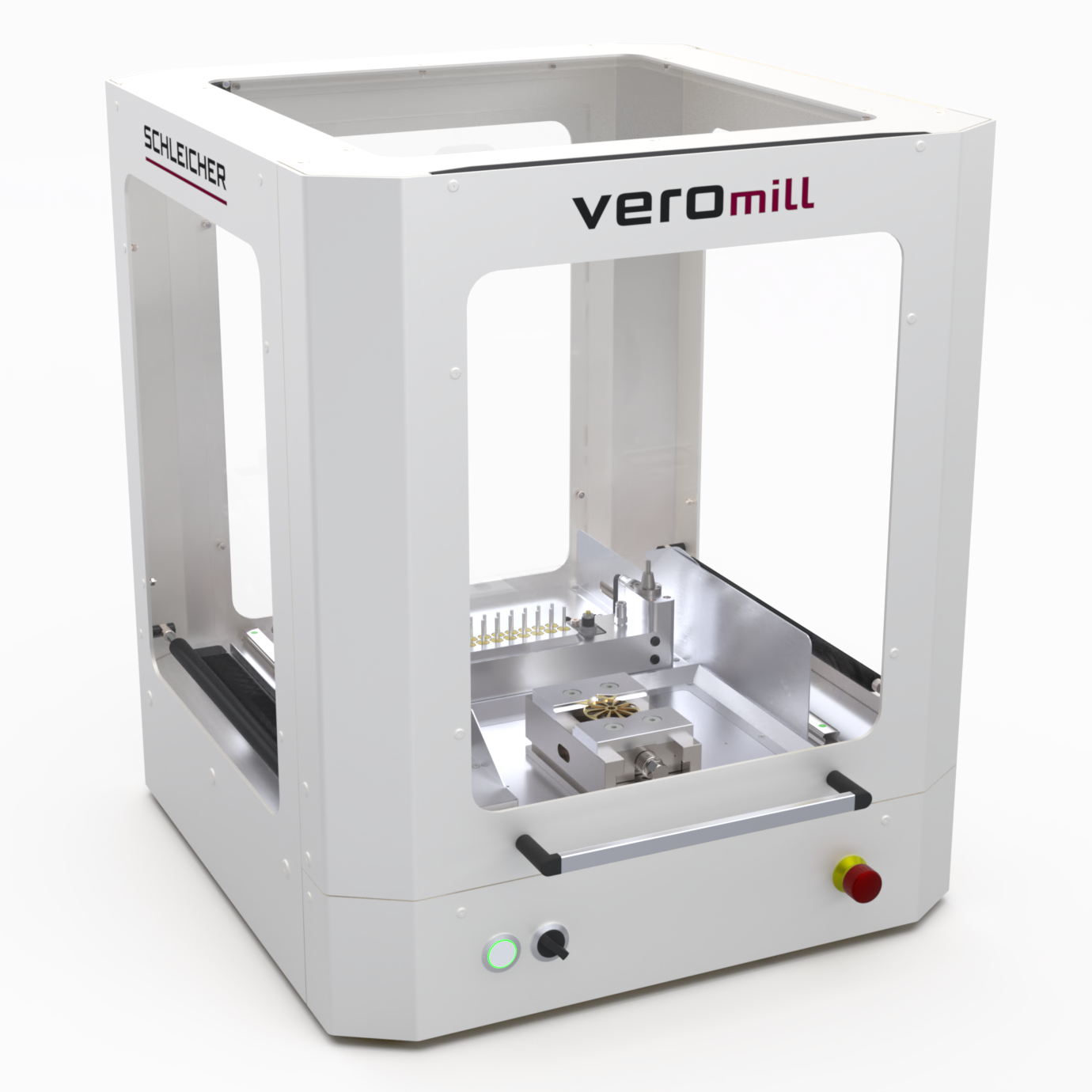

Compact Machining Center

VEROMILL

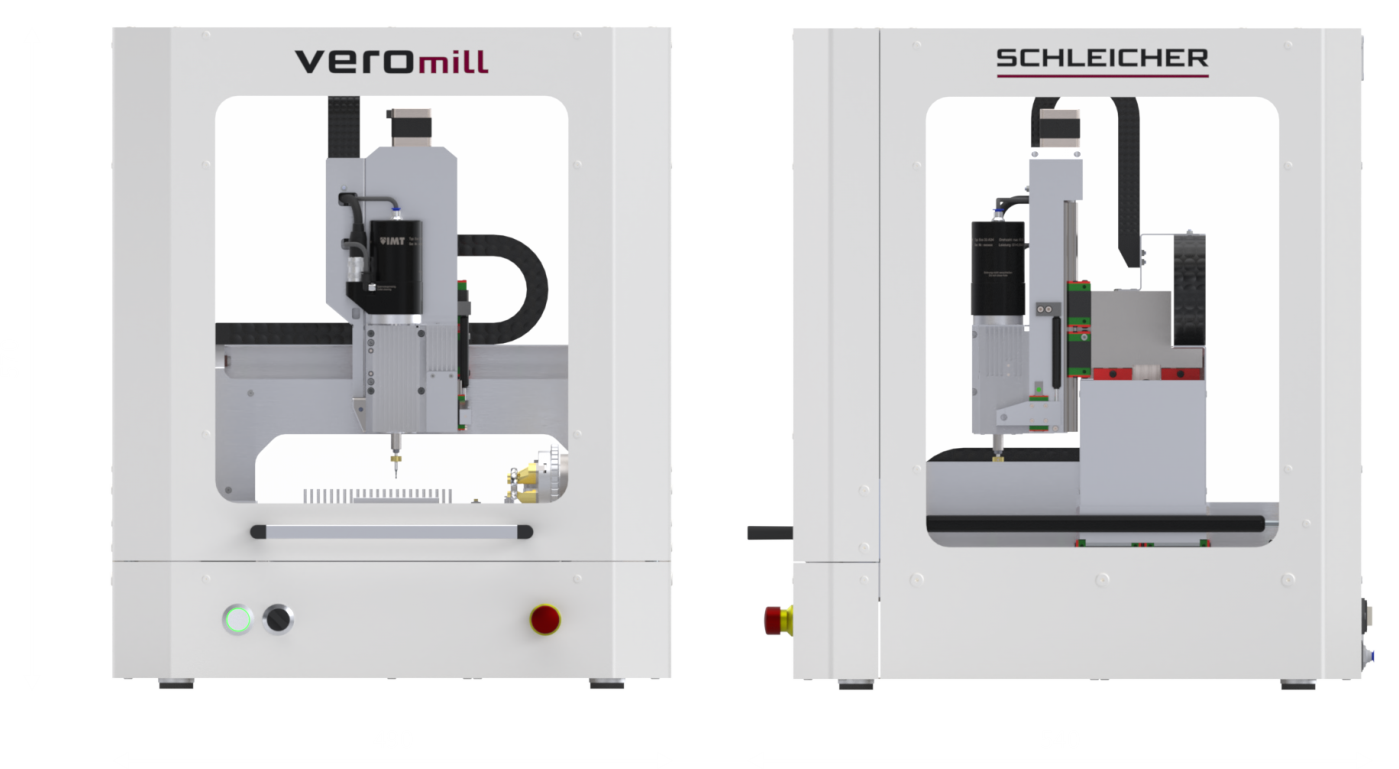

Discover the Veromill™, a precise and compact milling center for CNC manufacturing, micromachining and micromilling. Thanks to its innovative design, the Veromill™ has enormous stability and precision. Despite its small size.

Applications and industries: General CNC production, jewelry manufacturing, watchmaking, engraving, rapid prototyping, micromilling, stamp and tool manufacturing, microfluidics.

Features of Veromill milling machine

High precision

The innovative design, the selection of high-quality components and the precise assembly offer the highest precision of our cnc milling machine.

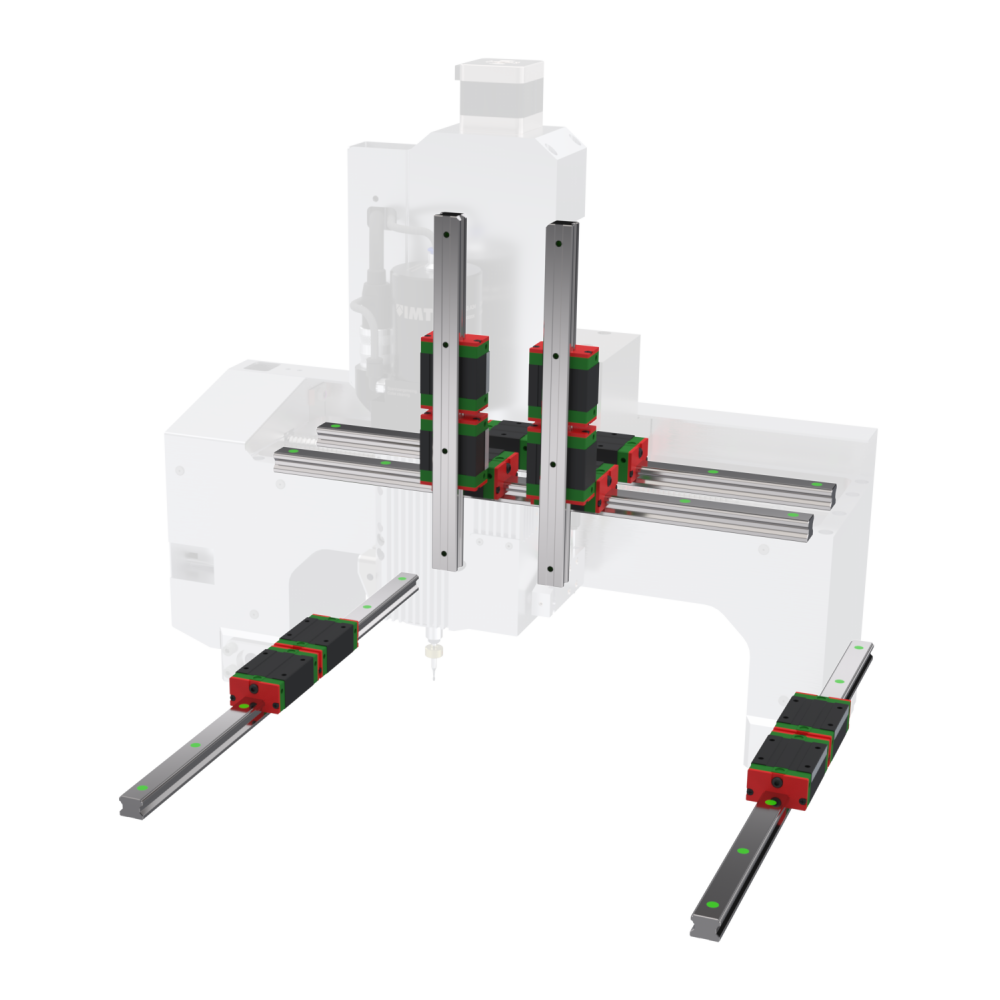

High structural stability and stiffness

The high structural stability of the compact milling center always guarantees the highest quality of the machined surfaces.

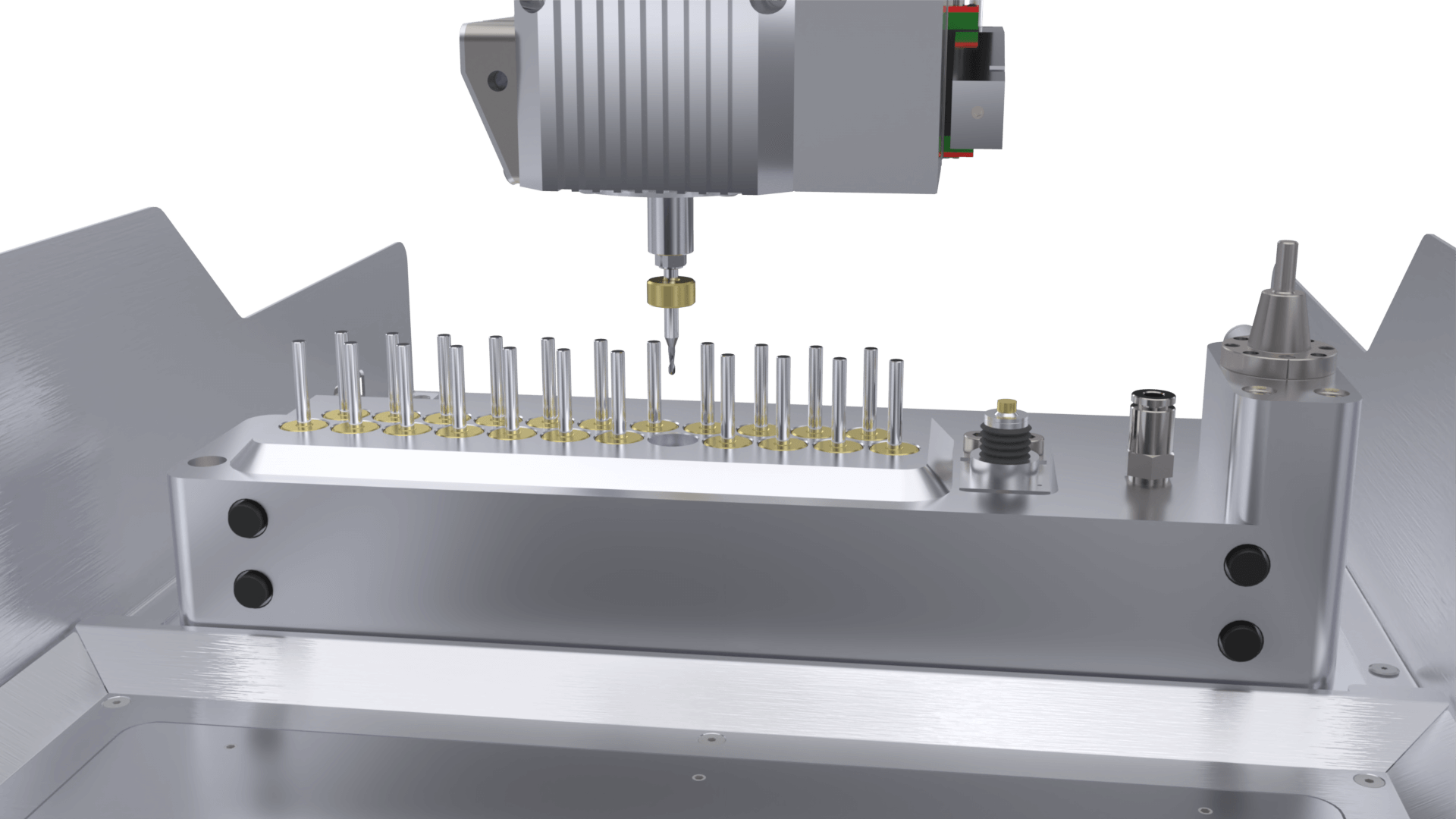

Automatic tool change with the CNC milling machine

Thanks to the integrated tool changing system with a capacity of 23 tool stations, the CNC milling machine can also be used to machine more complex applications automatically (available as standard).

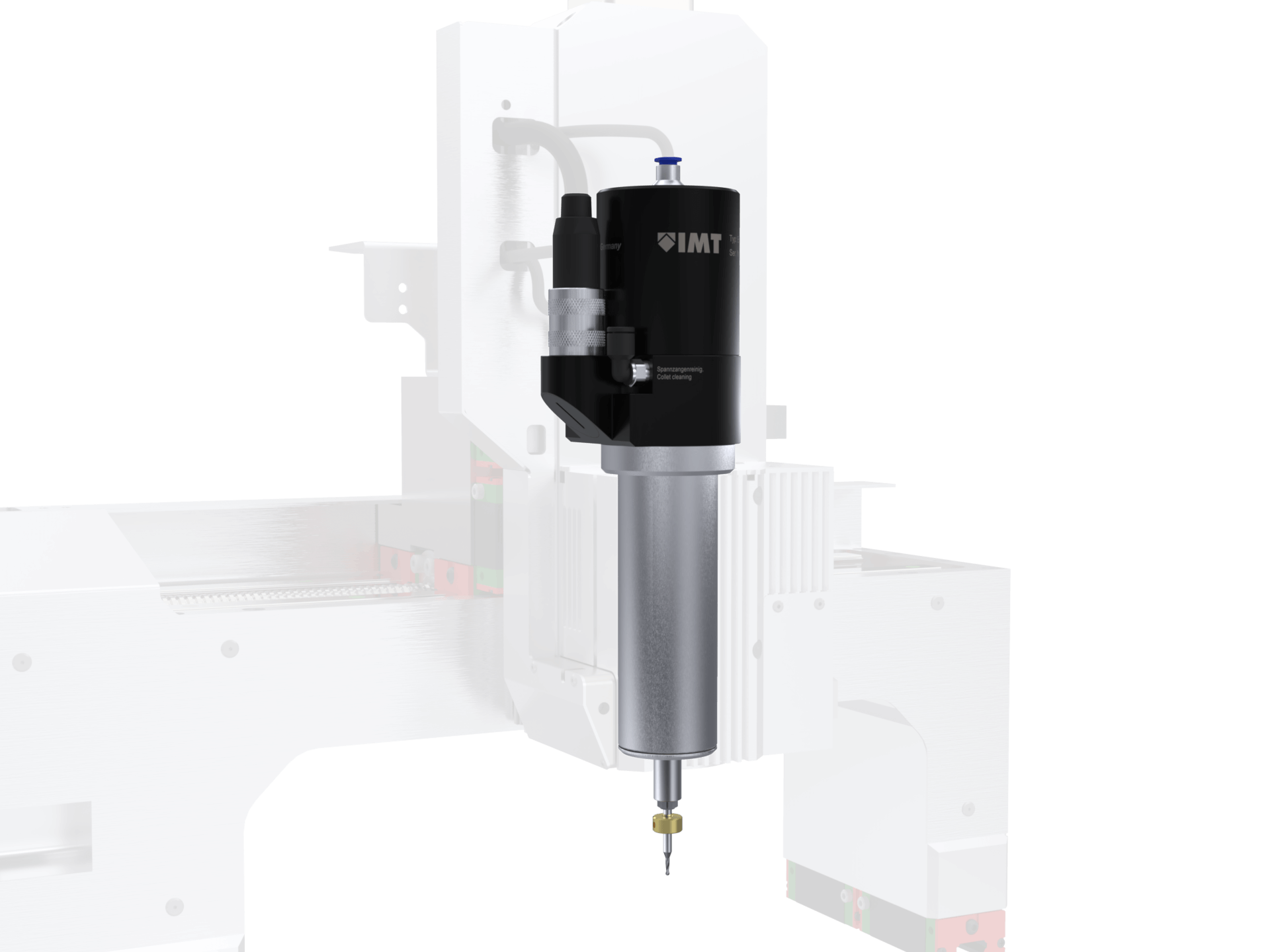

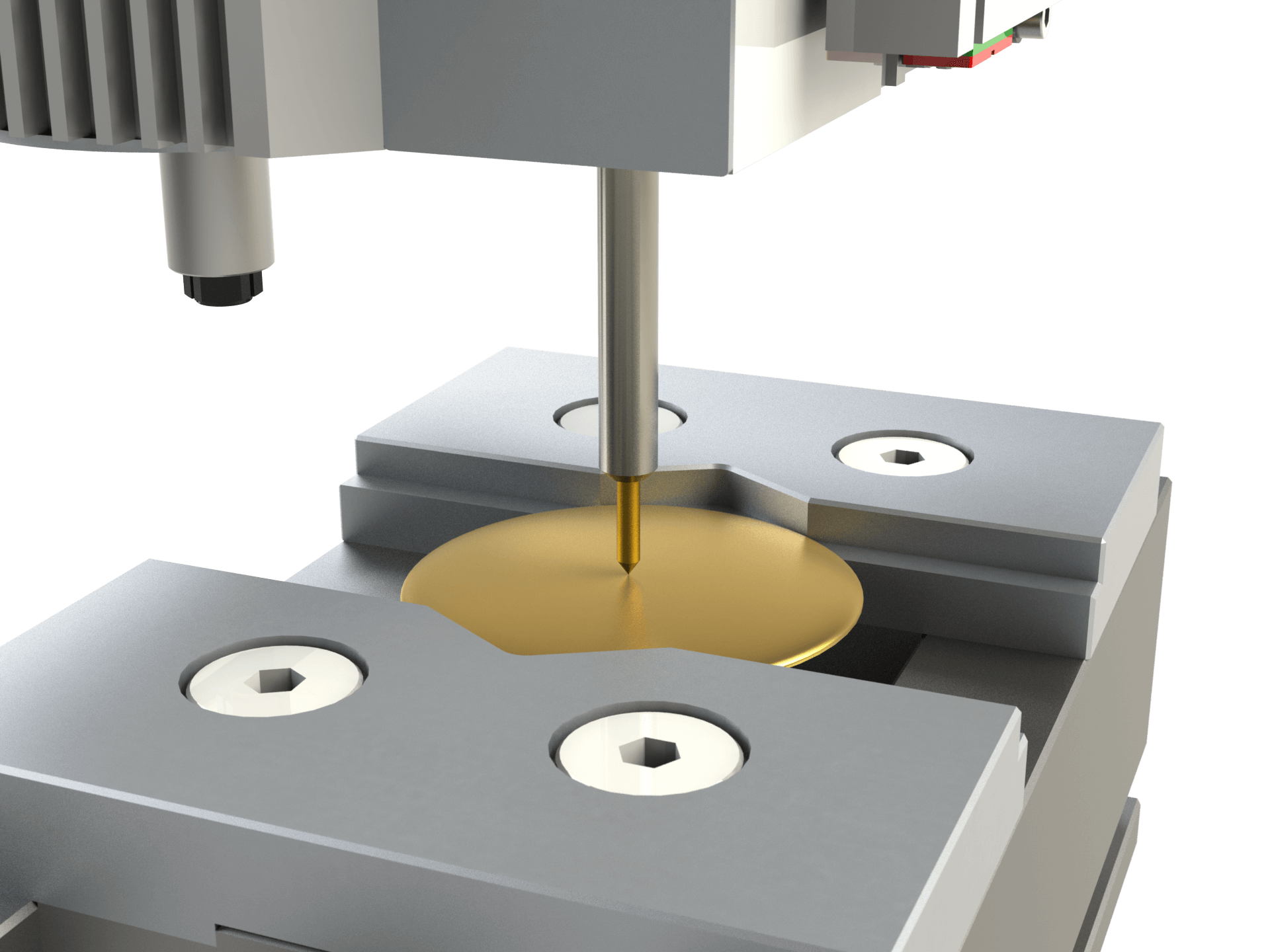

Tool cooling and lubrication (MQL)

Integrated tool cooling and lubrication as standard. Significantly longer tool life and surface quality with the milling machine for micromachining.

Precise milling spindle for up to 60,000 rpm

The high-performance milling spindle used provides increased cutting speeds and feed rates. Thanks to this, speeds of up to 60,000 rpm can be achieved with the milling center.

Product features of the CNC milling machine

Automatic tool change with the milling machine

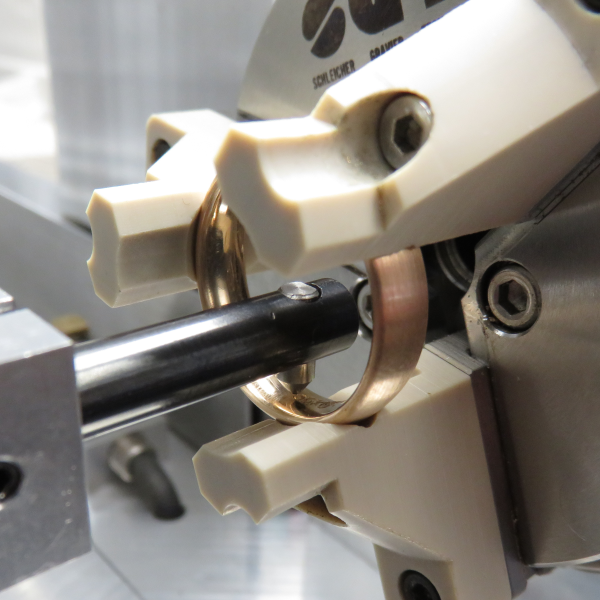

The Veromill™ machining center has an automatic tool change. With this, you can automatically insert and exchange your tools. Engrave or mill your jewelry with different tools without interruptions and fully automated. The tools are clamped pneumatically by means of a collet chuck. The tool magazine of the CNC milling machine includes 23 places and a receptacle for the measuring tip. A tool length sensor is integrated in the magazine to correct the different tool lengths. The tool magazine is located at the back of the machine. It is safely separated from the interior of the machine by a transparent panel.

Minimum quantity lubrication for cooling and lubrication of the tools

The standard equipment of the CNC milling machine includes fully integrated tool cooling and lubrication. This minimum quantity lubrication cools and lubricates the milling tools during machining by air and spray mist. Thus, significantly increase the tool life of your tools. In addition, the constant lubrication achieves a higher surface quality of your jewelry. The spray head of the lubrication system is completely integrated in the spindle block of the CNC machine for jewelry and does not have to be adjusted manually.

High structural stability

The compact milling center is equipped with backlash-free and stable guides. These are directly mounted to the machine's solid base supports. This enables us to achieve maximum rigidity and precision. This is directly reflected in the quality of your products. The axis drives of the Veromill™ are realized with preloaded recirculating ball drives. It achieves absolute freedom from backlash, longer tool life and more precise milling.

High-precision milling spindle with automatic tool change

The built-in high-performance milling spindle ensures increased cutting speeds and feed rates. Thanks to this, speeds of up to 60,000 rpm can be achieved. The engraving and milling times are significantly reduced. The optimum speed can be set variably depending on the material or tool. The tools are always clamped at the center of the milling spindle using a collet chuck. This guarantees a long tool life due to optimum concentricity. The tools are clamped by means of pneumatically actuated direct shaft clamping. This enables automatic tool changes.

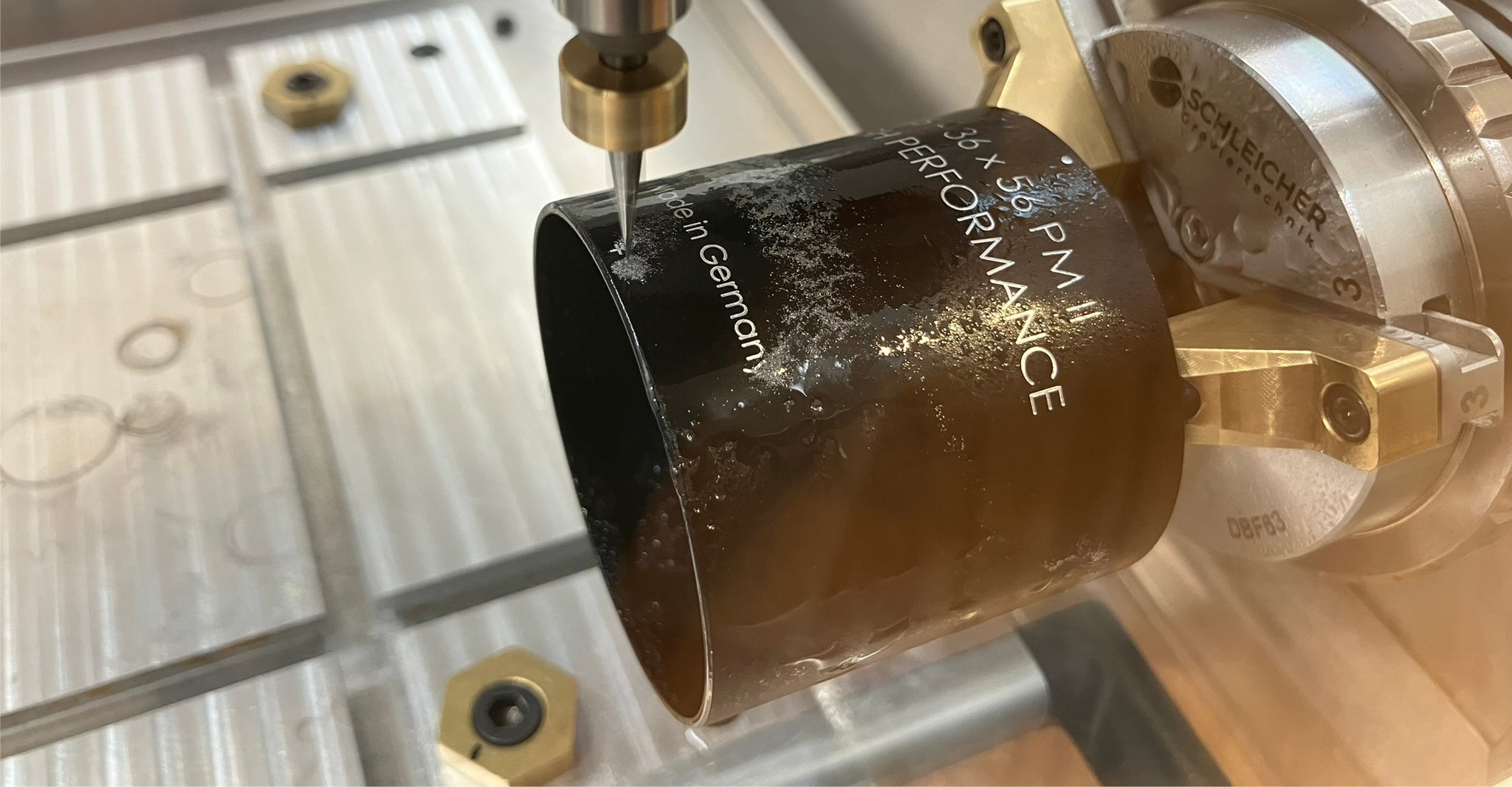

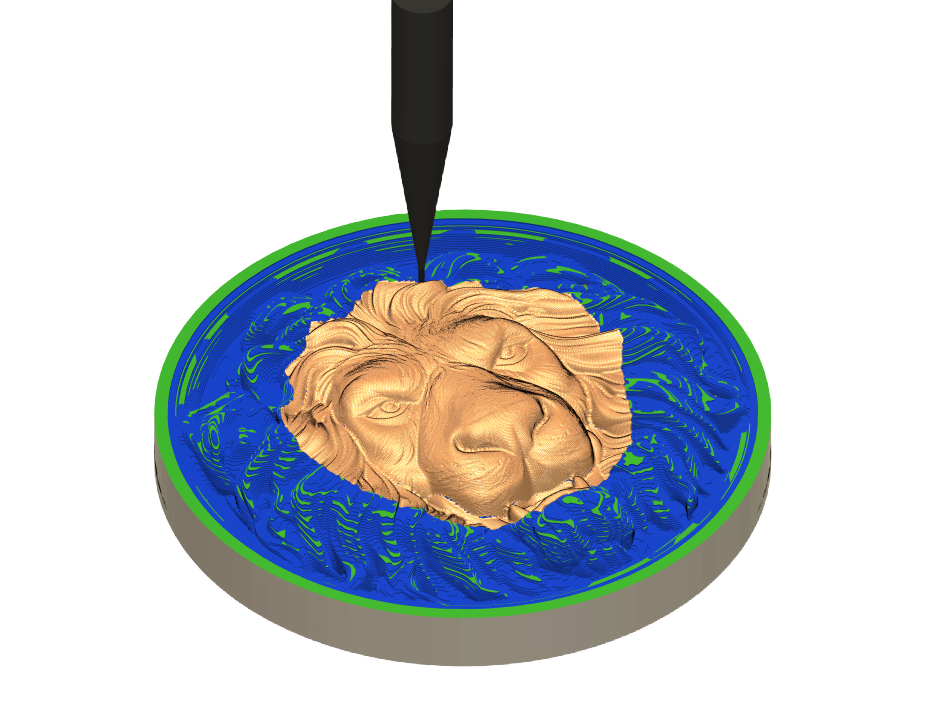

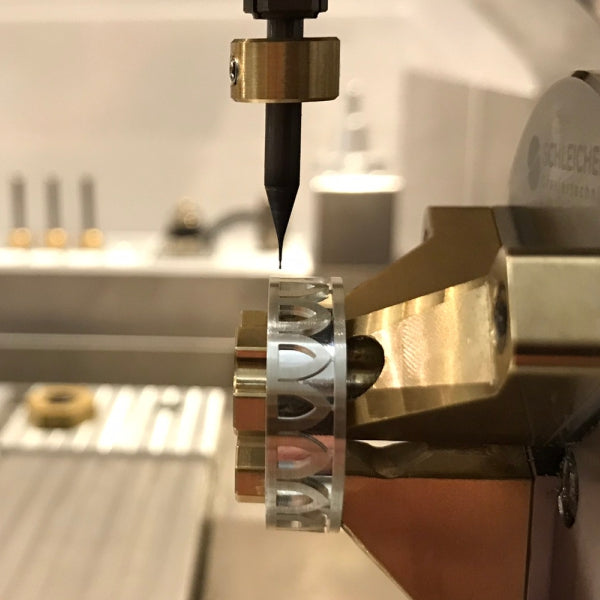

Measuring system for curved surfaces

The CNC milling machine's fully integrated measuring system is unique. This allows curved surfaces to be milled or engraved quickly and easily. Drawings and designs can be simply created in 2D, while the Veromill™ machines the curved surfaces in 3D after automatic measurement. This is an advantage over conventional engraving depth controllers, where the engraving depth has to be set manually. In addition, the electronic height compensation increases tool life, as the optimum cutting depth for the tool is used.

Innovative machine housing

The safety concept of the jewelry milling machine consists of a stable sheet metal housing in cube format. The transparent glass panes provide an optimal view of all parts of the machine. The door of the CNC milling center is designed as a front lifting door. This makes it very easy to open the machine and load it with jewellery and workpieces from the front. High-performance LED strips are installed in the upper area of the housing and thus always ensure optimal illumination of the machine interior. Impress your customers with the innovative housing design of the Veromill™.

Complex milling or 3D engraving

Whether you want to produce simple engravings, complex milling or 3D engravings. TheVeromill™offers you sufficient flexibility, stability and potential for a variety of different machining operations. All axes of the CNC milling machine are controlled precisely and simultaneously. Depending on the machine variant: either 3- or 4-axis simultaneous milling.

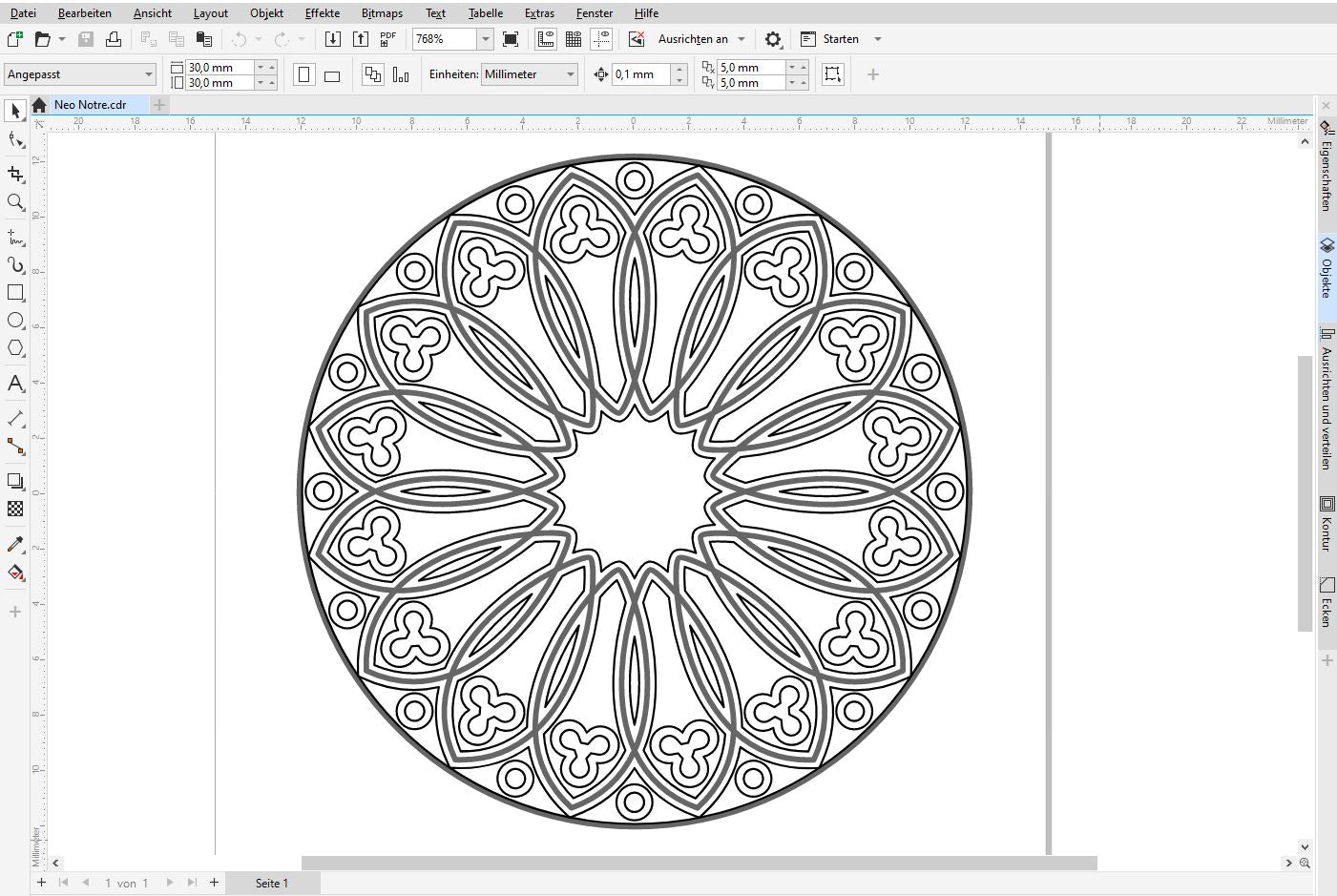

User-friendly software

The GraversPro™ software specially developed for our CNC machines makes brilliant engraving quick and easy. Whether engraving, cutting or milling. The software enables you to perform all types of machining such as internal ring engraving, external ring engraving and flat engraving. It doesn't matter whether you want to create simple or complex engravings. GraversPro™ always guarantees professional work thanks to advanced functions such as retracting and extracting, tool changing, drilling and travel direction settings.

Of course, you can also use the VEROMILL with other CAM software such as Autodesk Fusion 360. The CNC controls of our machines are flexible and can work with all common CAD/CAM systems.

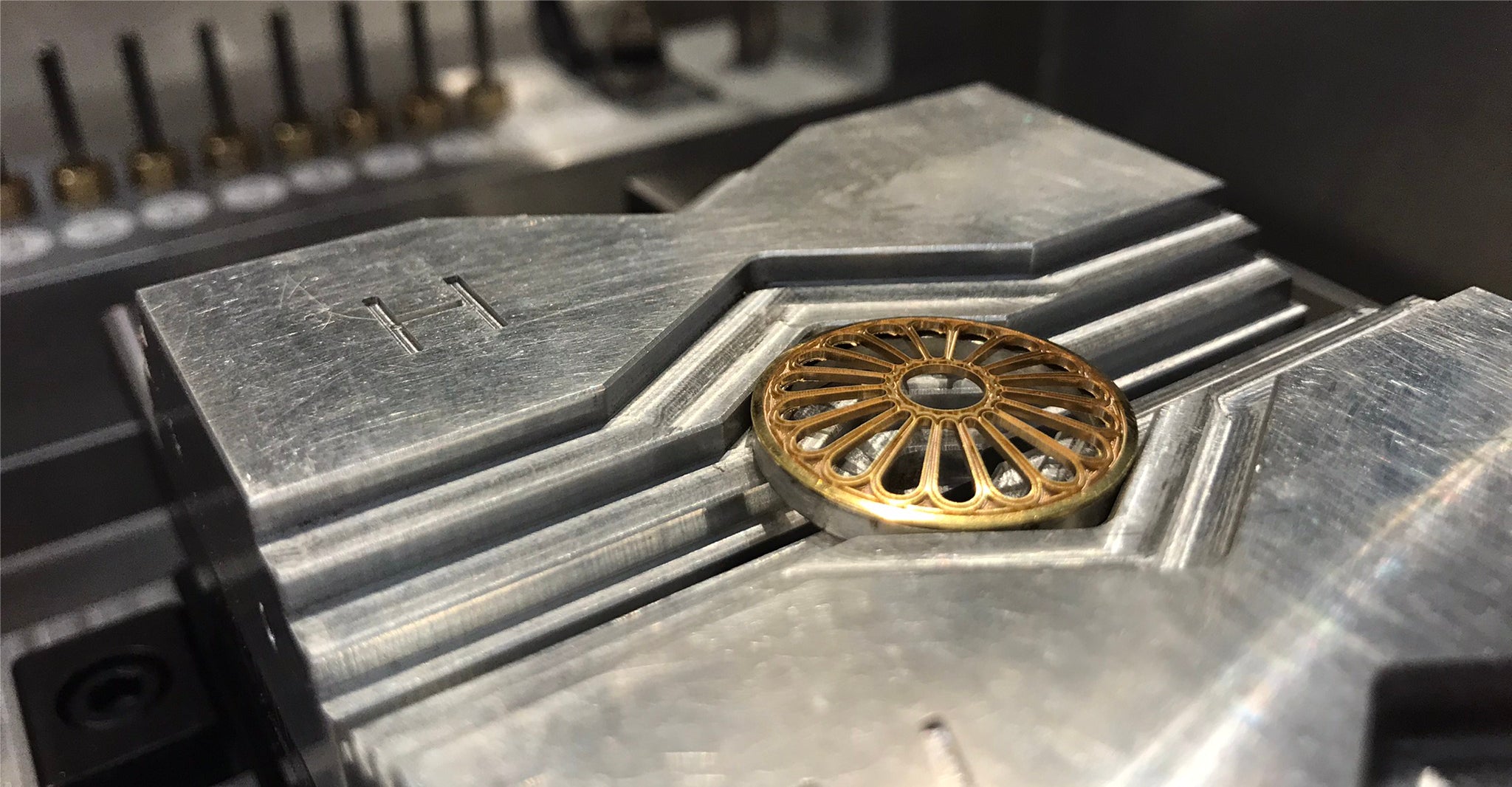

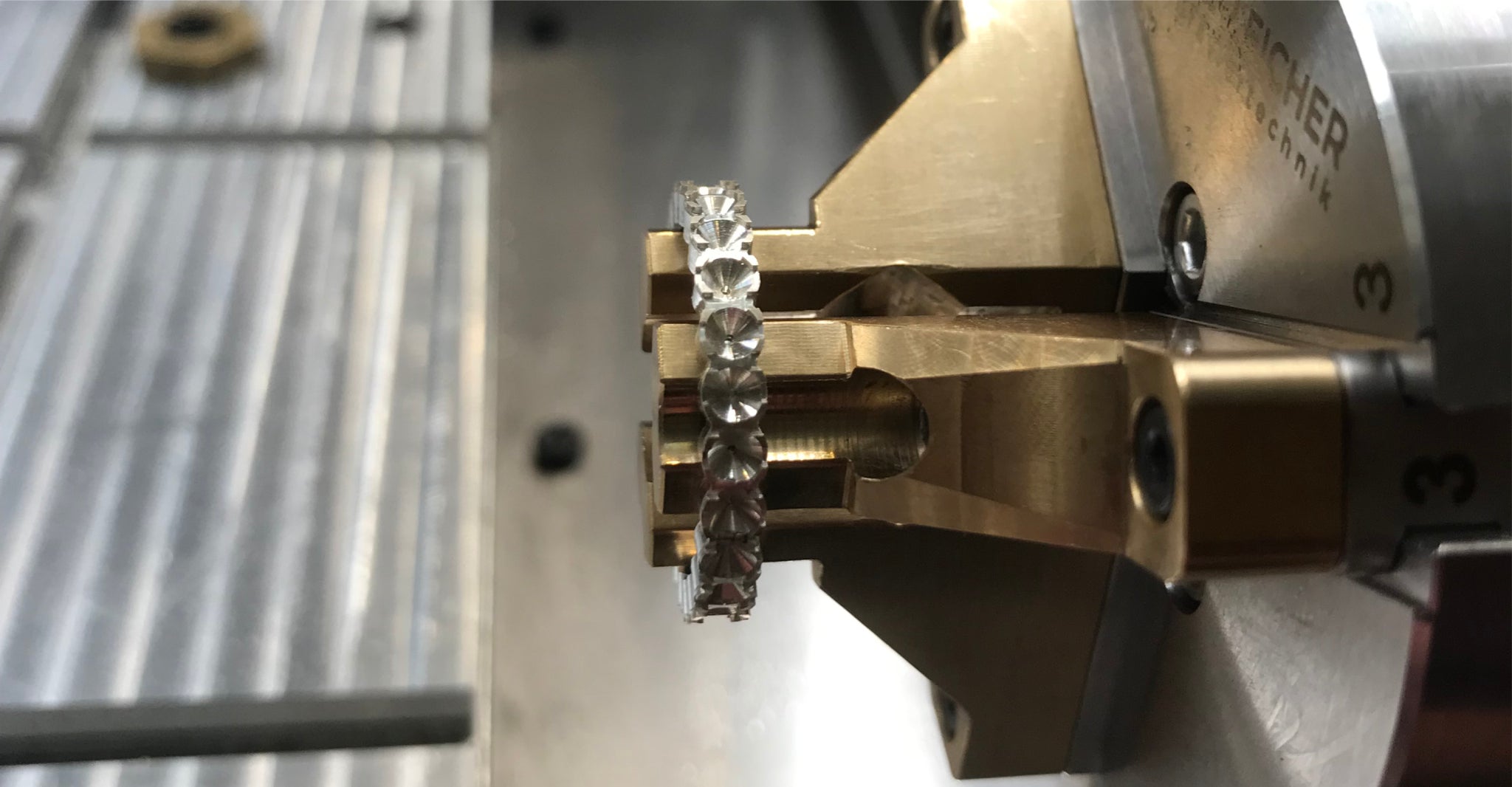

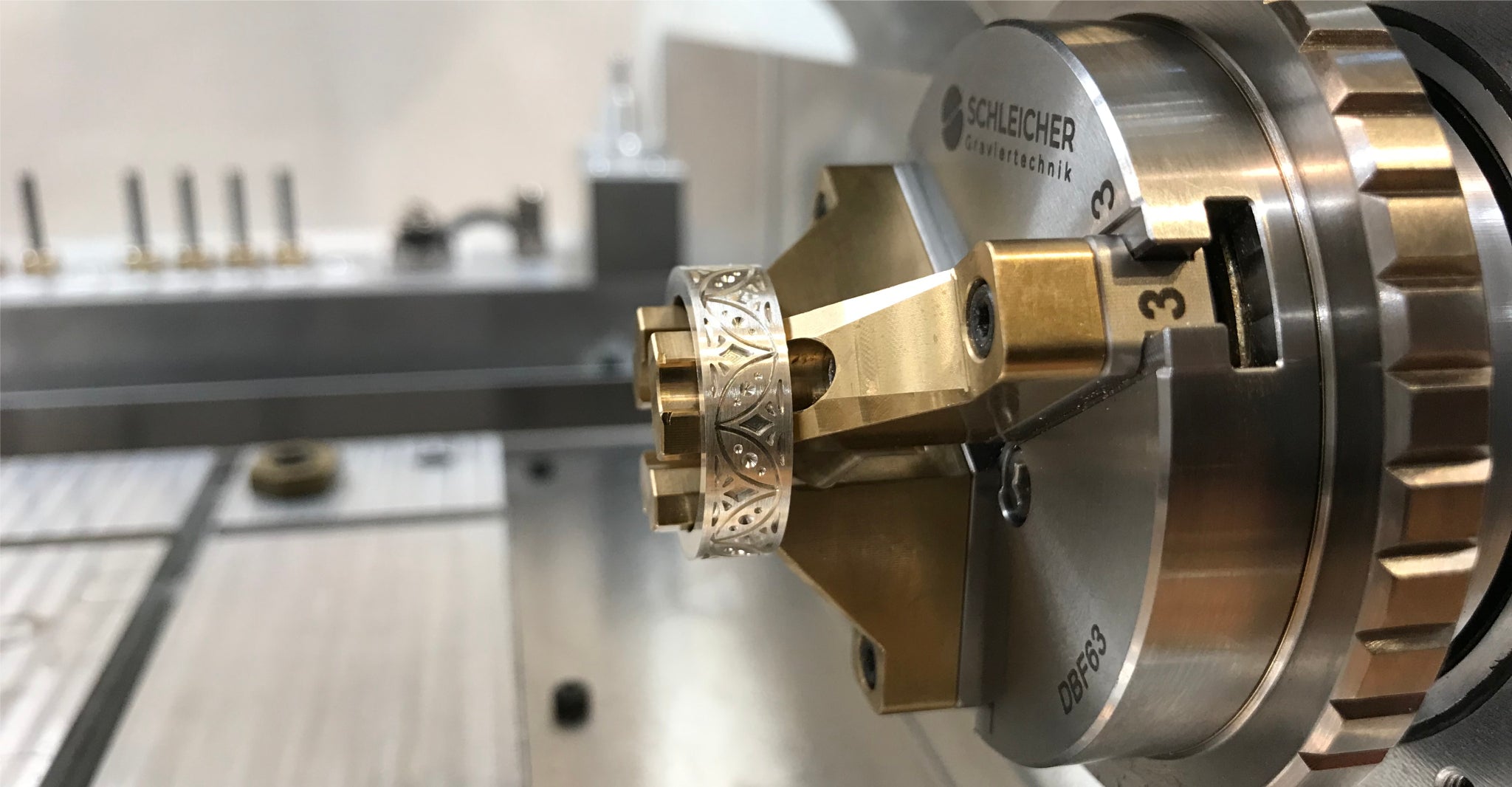

Jewelry produced with the Veromill milling machine

Our customers produce these pieces of jewellery on the Veromill™

Applications of the milling center for micromachining

Machining types of the CNC milling machine

4-Axis Simultaneous Milling

3-Axis Simultaneous Milling

Internal engravings

VEROMILL

Further information and links to the milling machine for jewelry, micromachining and micromilling.