Professional Desktop CNC Milling Machine | Engraving Machine

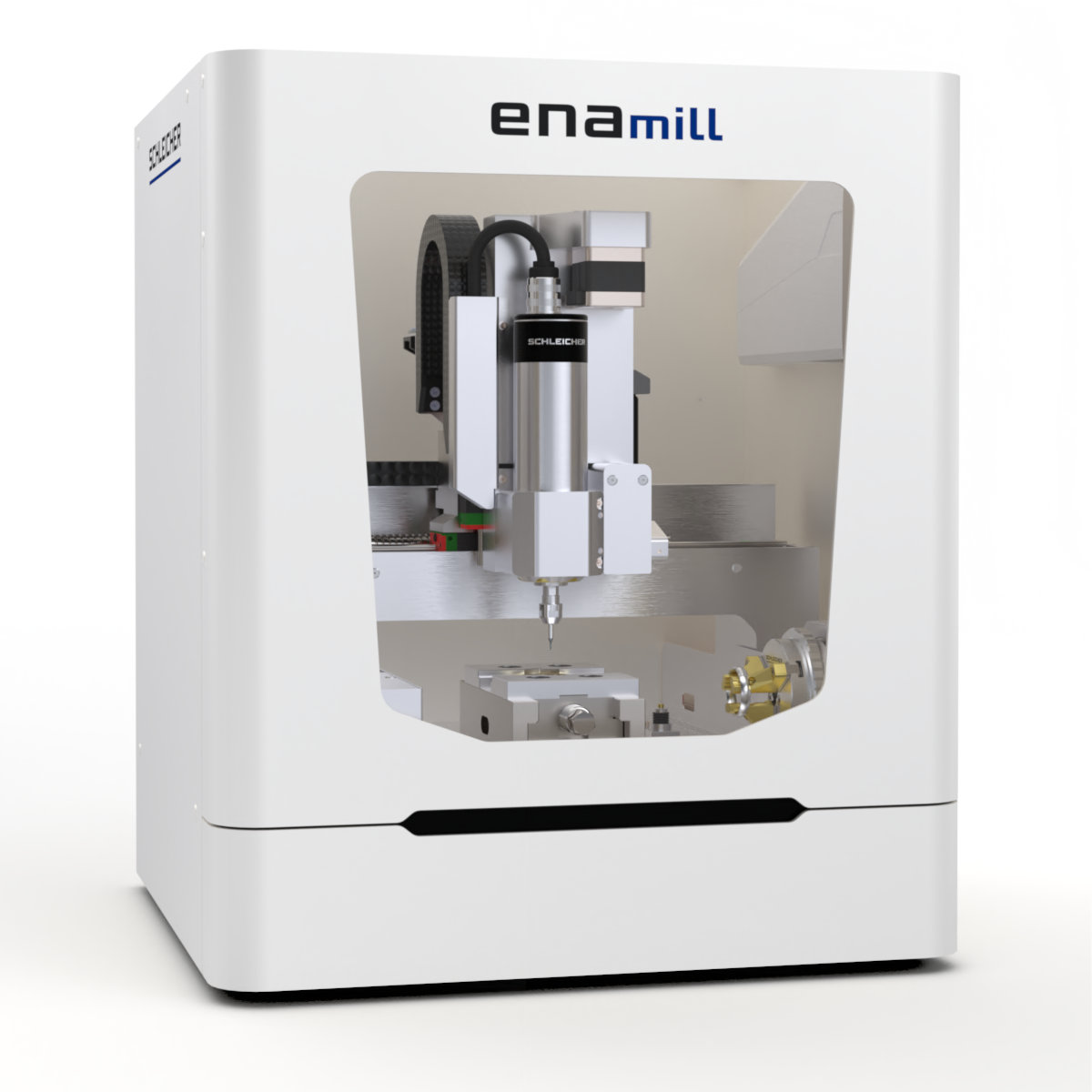

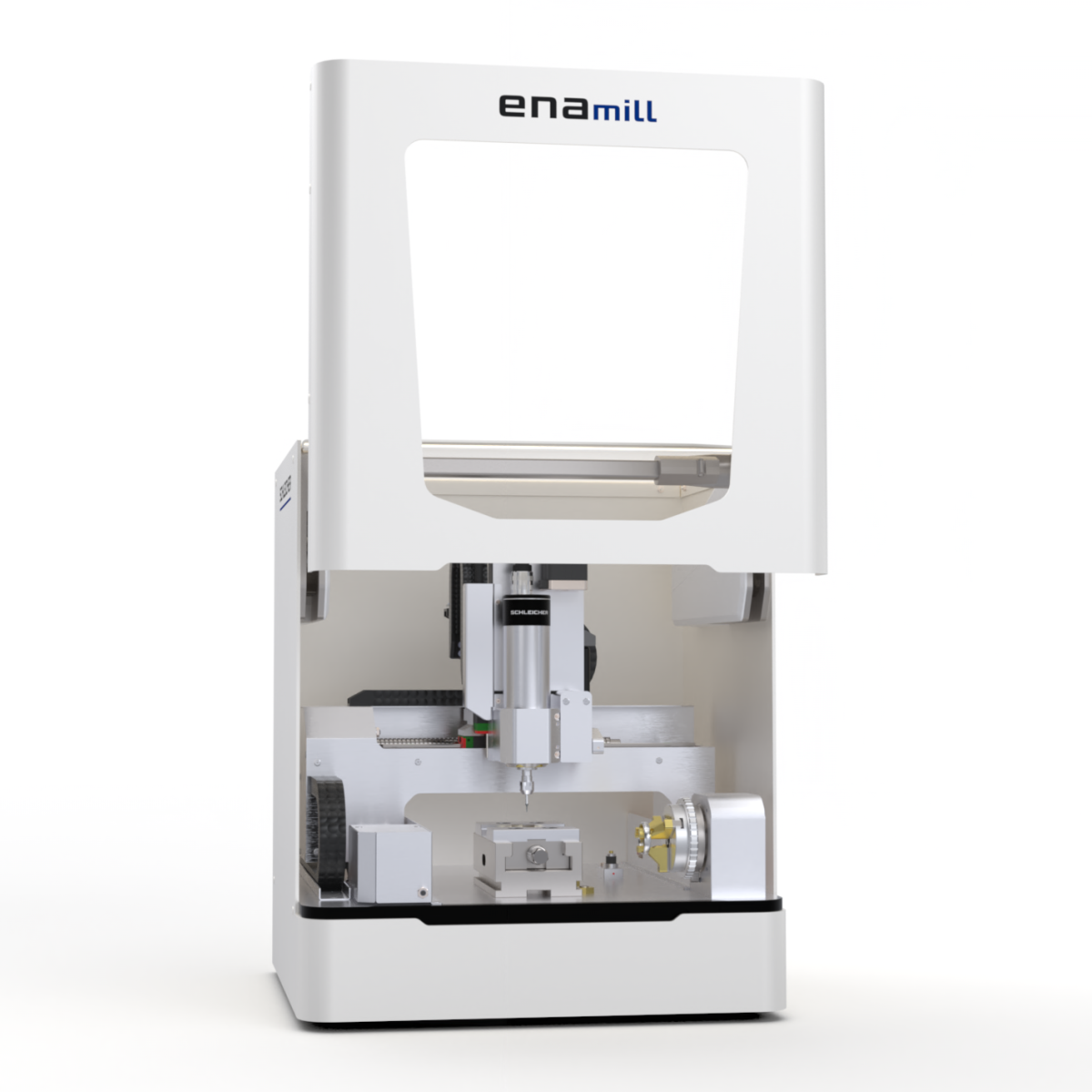

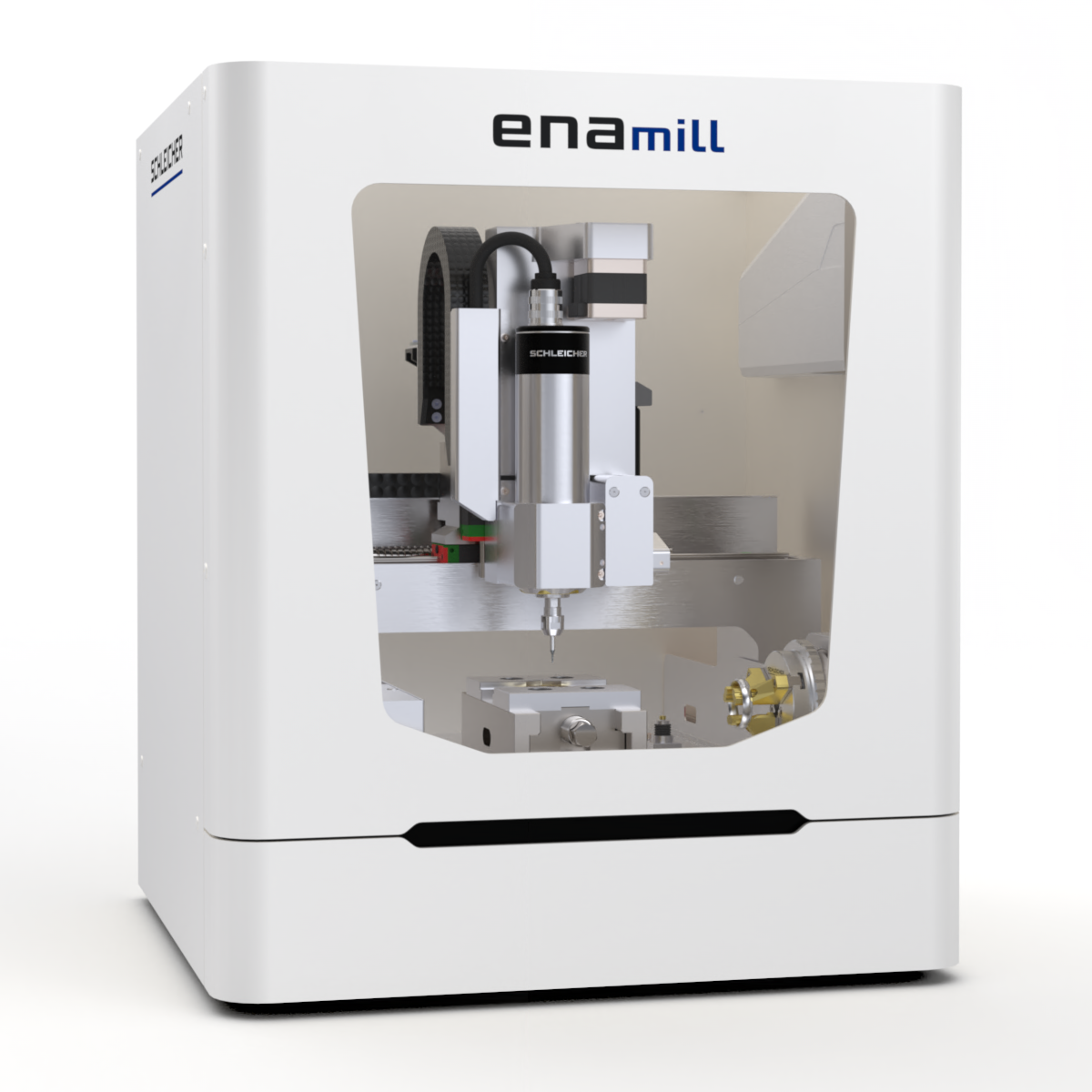

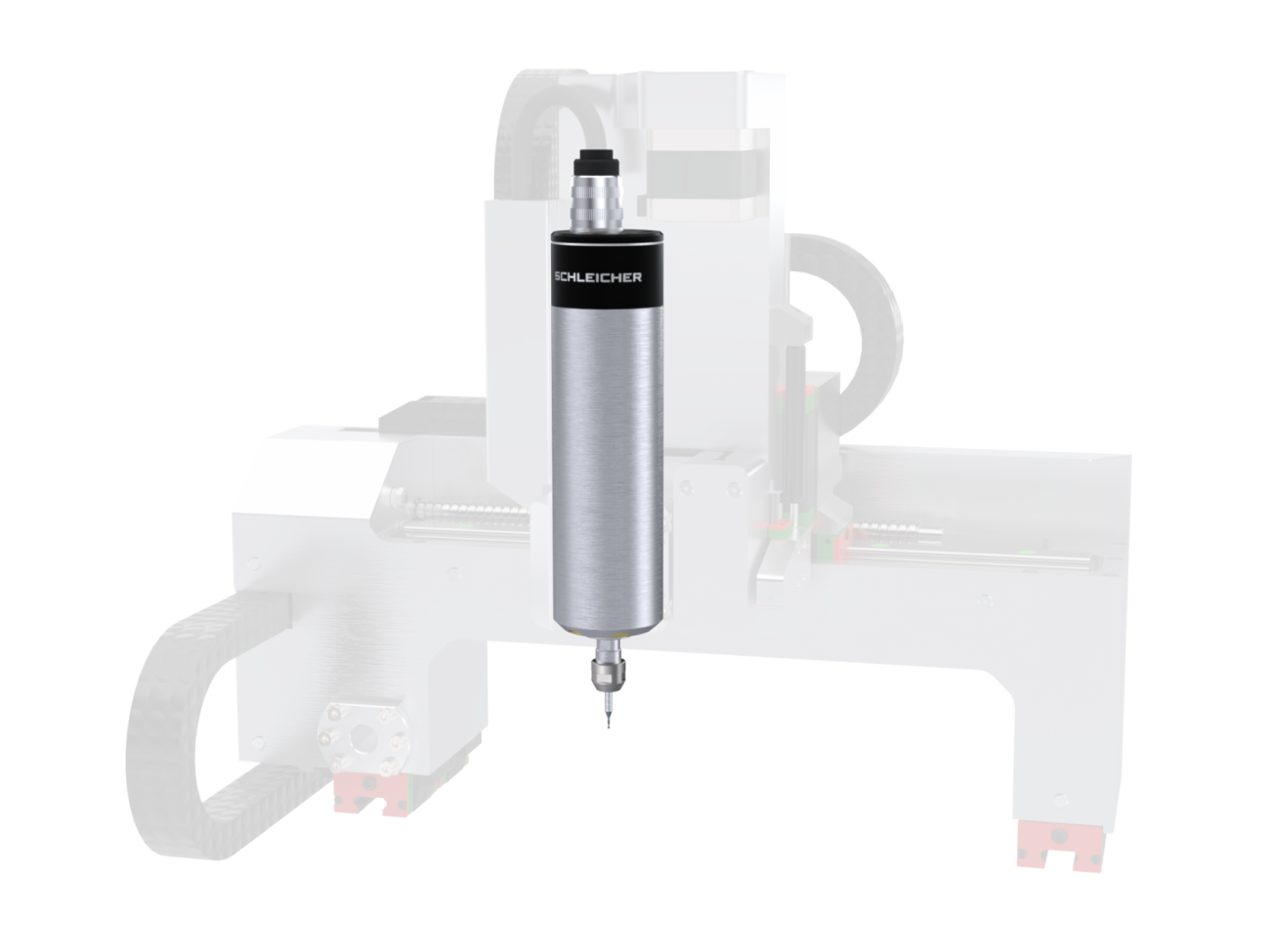

ENAMILL

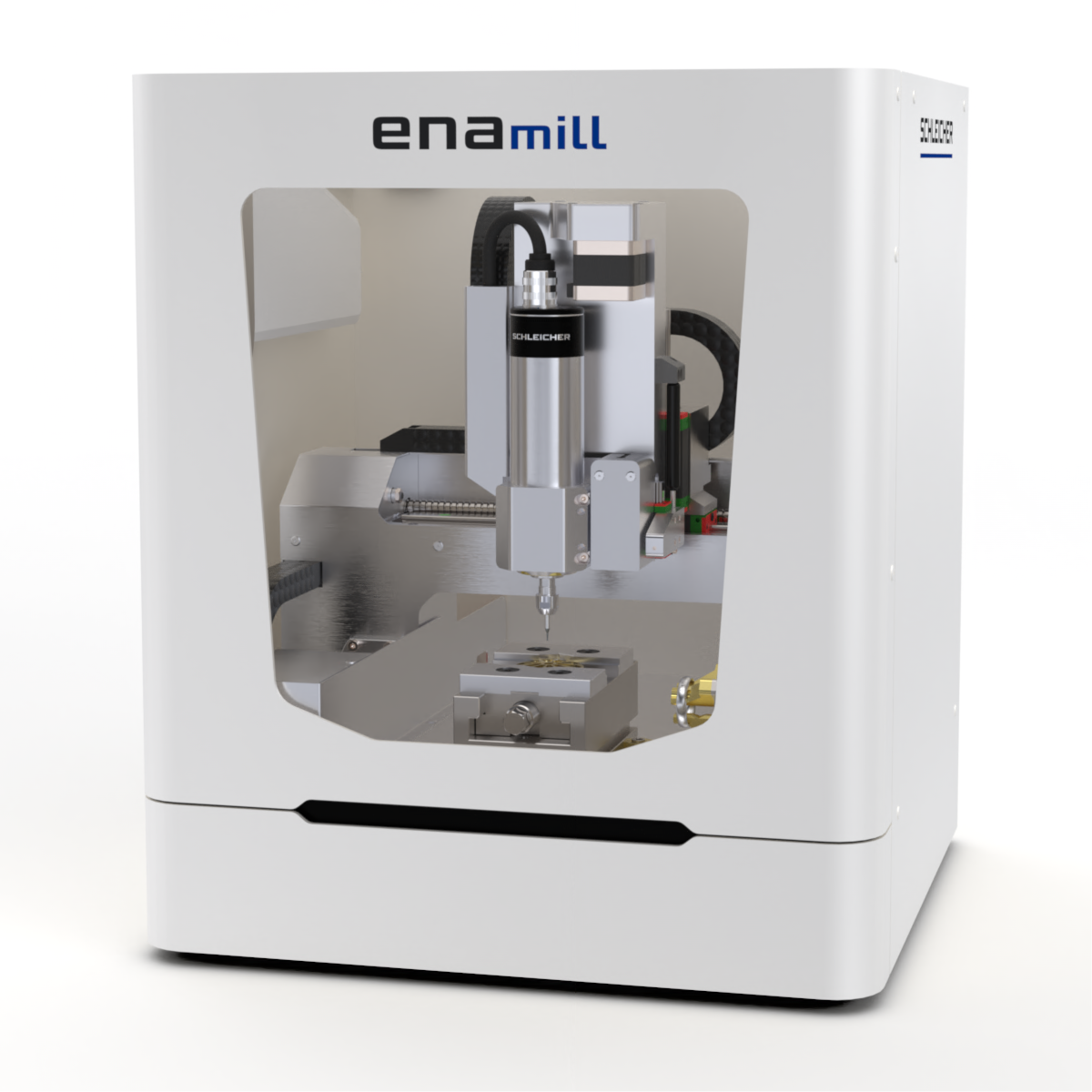

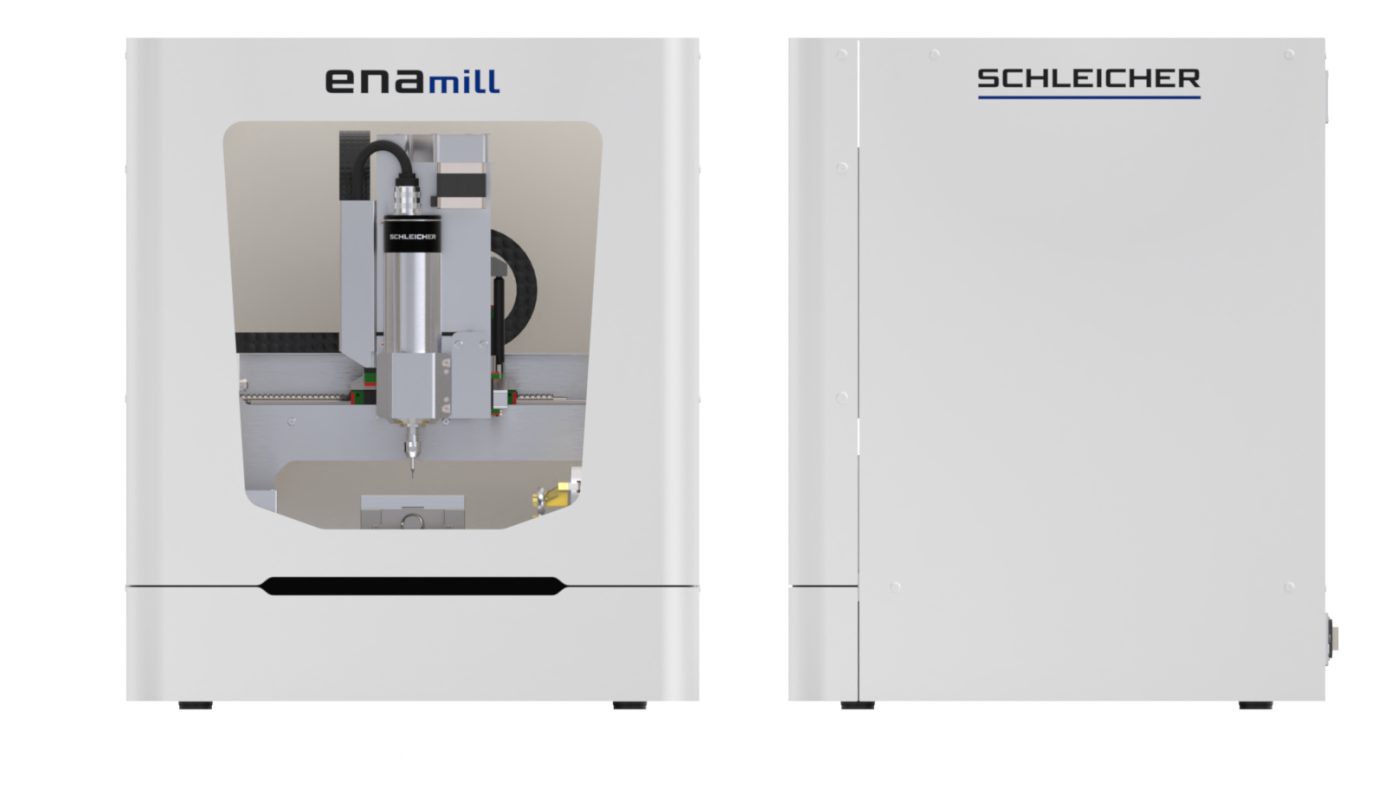

Discover the innovation for milling and engraving your workpieces or jewelry with the ENAMILL™. Precise and flexible, the engraving and milling machine adapts perfectly to your applications, products and jewelry. An enrichment for every workshop and every store.

Applications and areas of use: General CNC production, jewelry manufacturing, watch manufacturing, engraving of jewelry and rings, engraving of signs and nameplates, stamp engraving, coin engraving, medal engraving, cutting and milling of jewelry, 3D engraving and relief milling, stamp production made of tool steels, nameplates, coins and medals.

Precise engraving machine.

The rock-solid engraving machine design guarantees highest precision during engraving or milling of your jewelry. Basic components accurate to the micrometer, the use of high-quality machine components and exact assembly result in a precision that leaves nothing to be desired. Precision made in Germany.

Powerful jewelry engraving machine.

Due to the innovative machine concept, our jewelry engraving machine achieves the highest stability and rigidity. Reduce your tool wear and get machining surfaces of the highest quality. Highly polished machining surfaces are achieved when engraving with the CNC milling machine, giving your jewelry and workpieces an incomparable value.

Unique milling machine.

The patented measuring system integrated into the engraving machine enables you to precisely measure your workpiece surfaces. The measurement data thus obtained is used to compensate for curved or uneven workpiece surfaces. This allows you to machine curved and three-dimensional jewelry surfaces despite simple 2D drawings. This novel machining process is a technical revolution for which we have obtained a patent. In addition, electronic compensation reduces tool wear and manual adjustment of engraving depths is a thing of the past.

Automated CNC engraving machine.

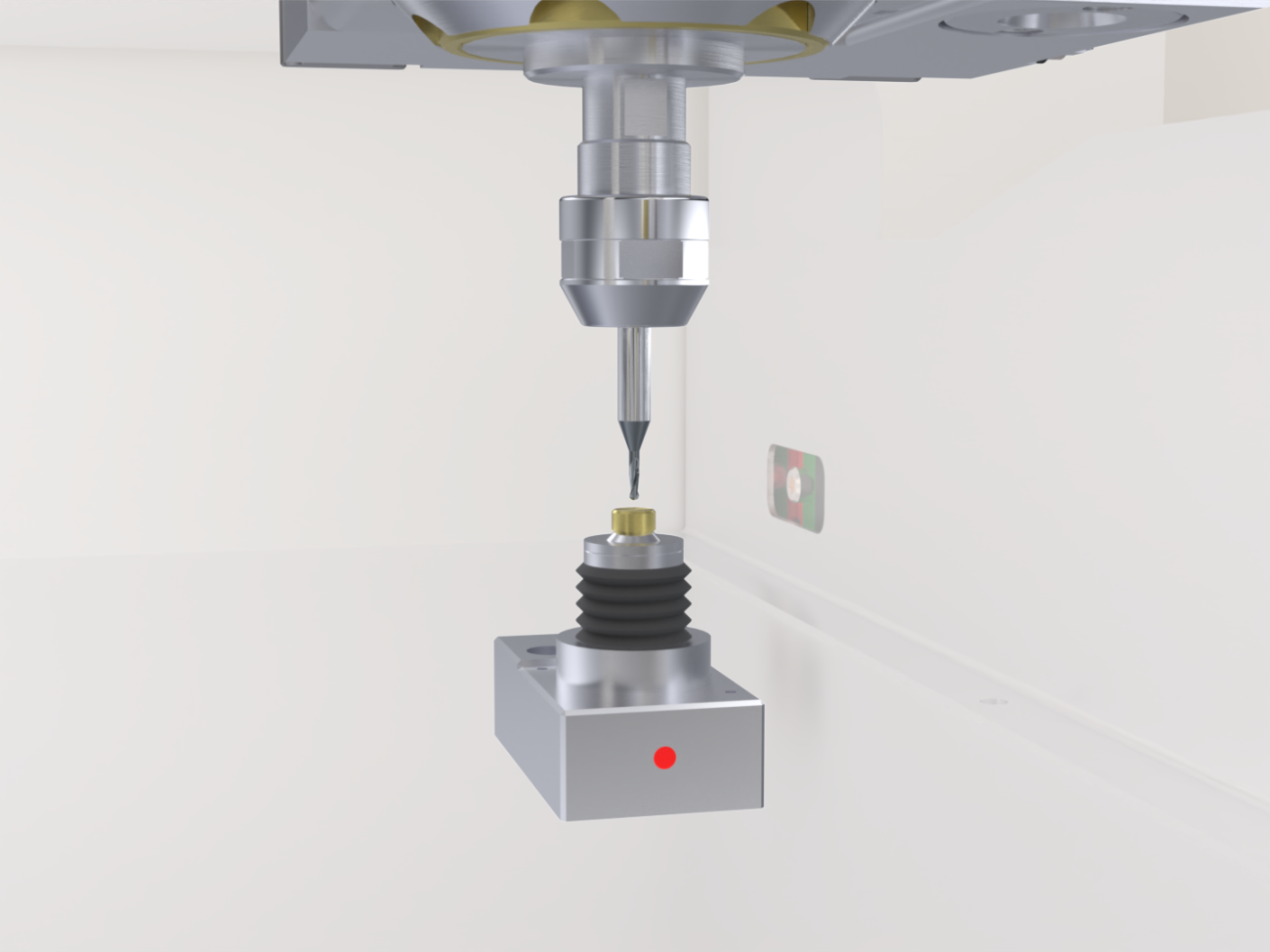

Thanks to the integrated tool sensor, different tool lengths are automatically measured and corrected. Workpiece positions and zero points are automatically detected and set by the CNC engraving machine's measuring system.

Machining types of the Engraving Machine

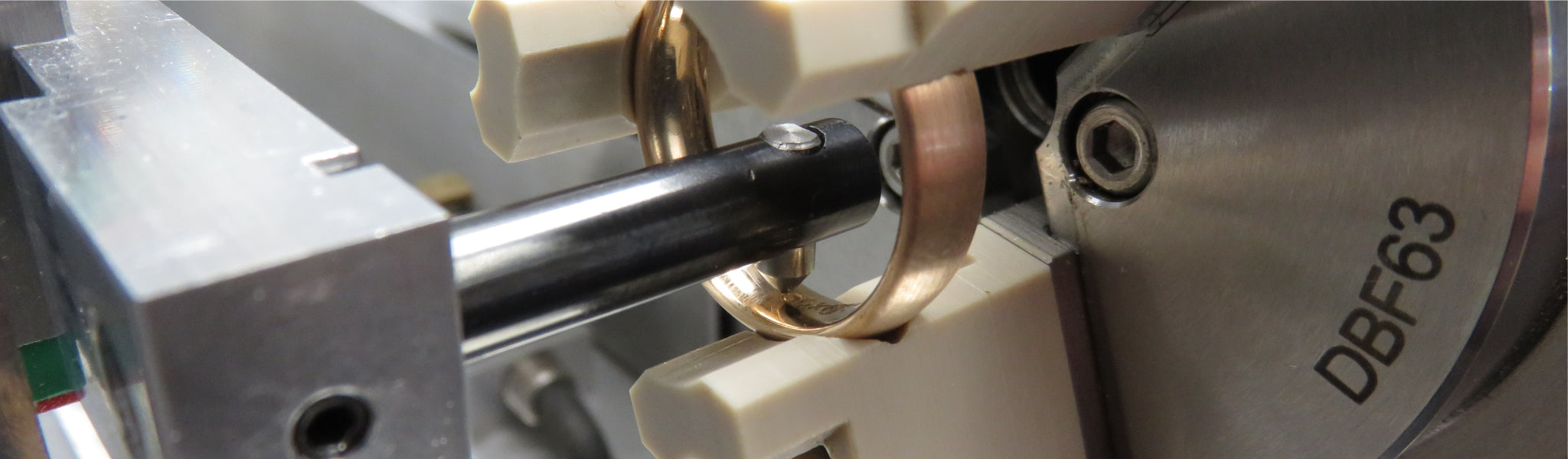

Inside engravings with engraving machine

Outside machining with the CNC engraving machine

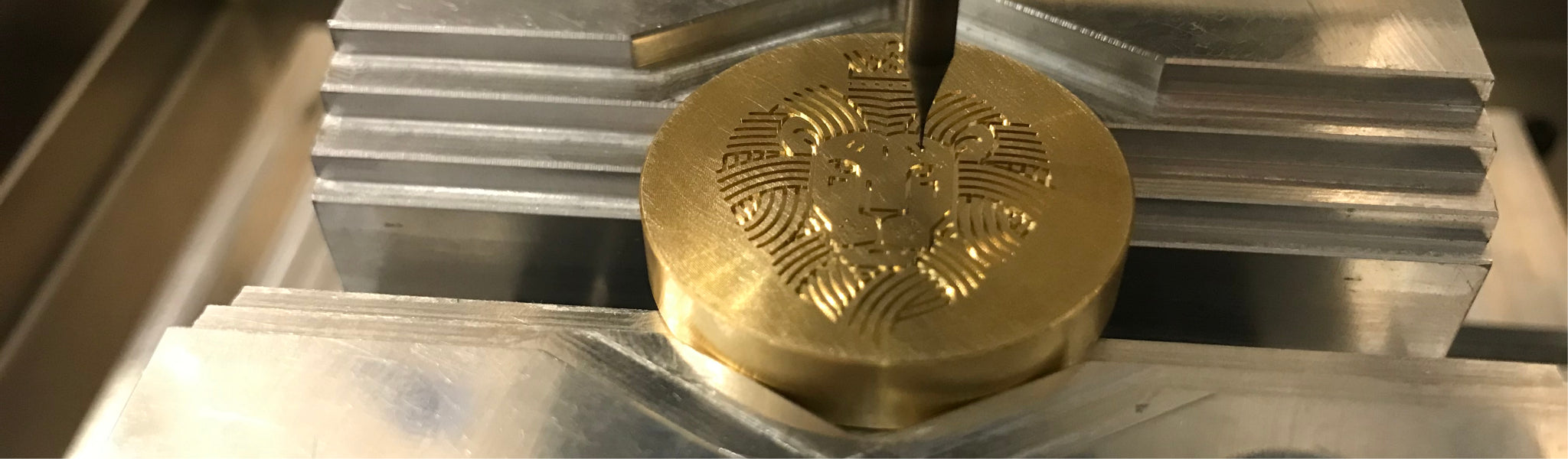

Flat machining with the engraving machine for jewelry

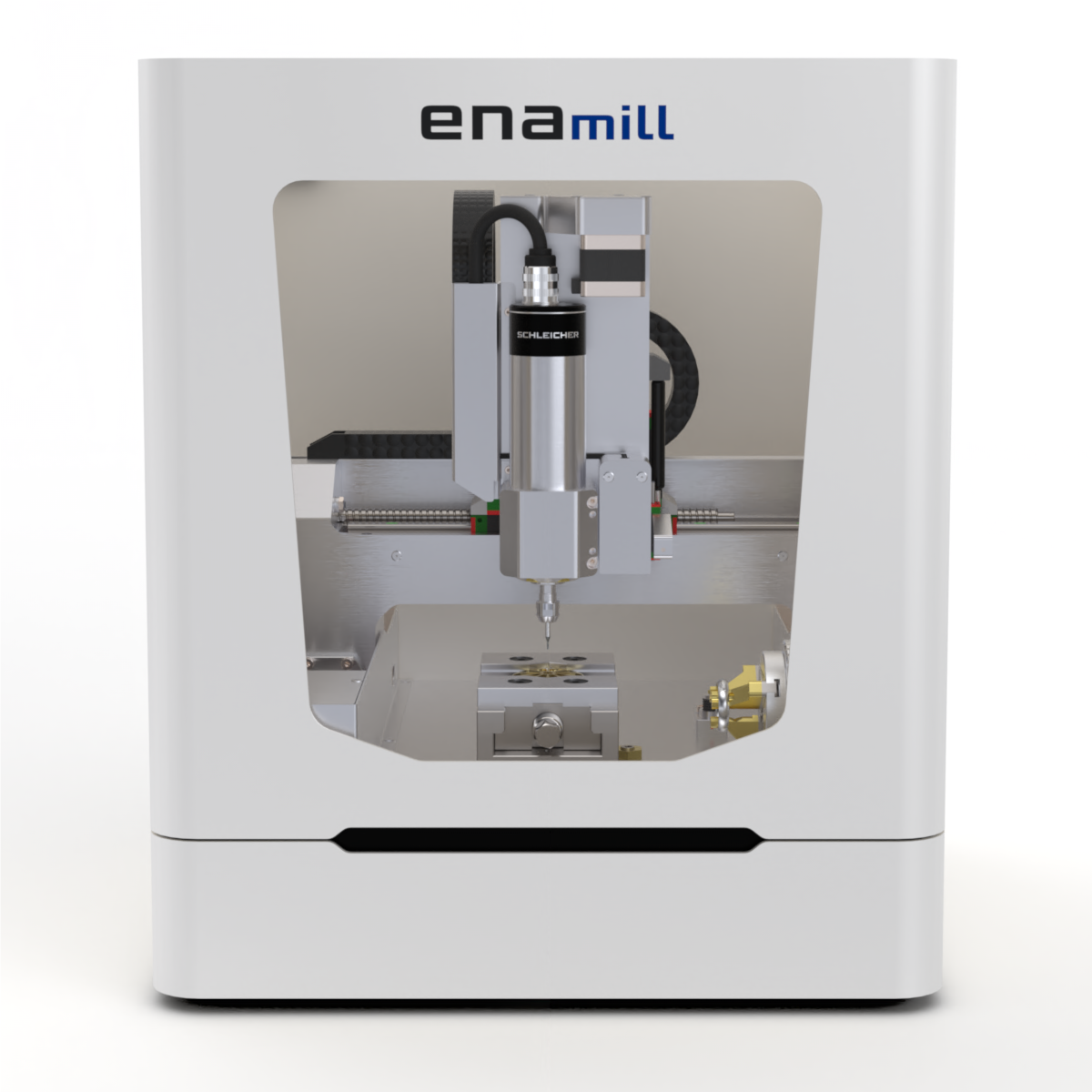

All-in-one CNC machine

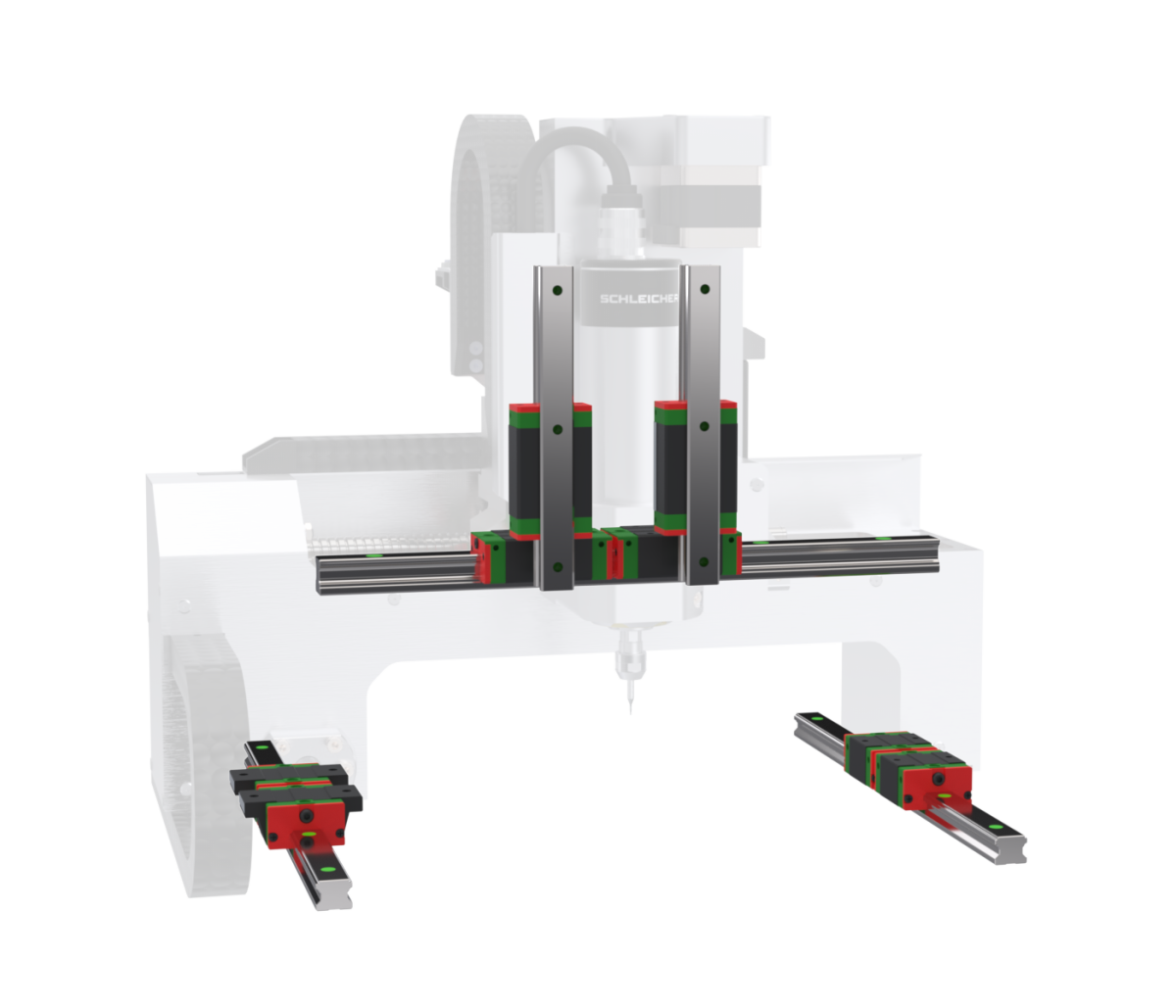

High structural stability

Precise drive systems

High performance milling spindle

Automatic measurement

Elegant machine housing

High flexibility

User-friendly software

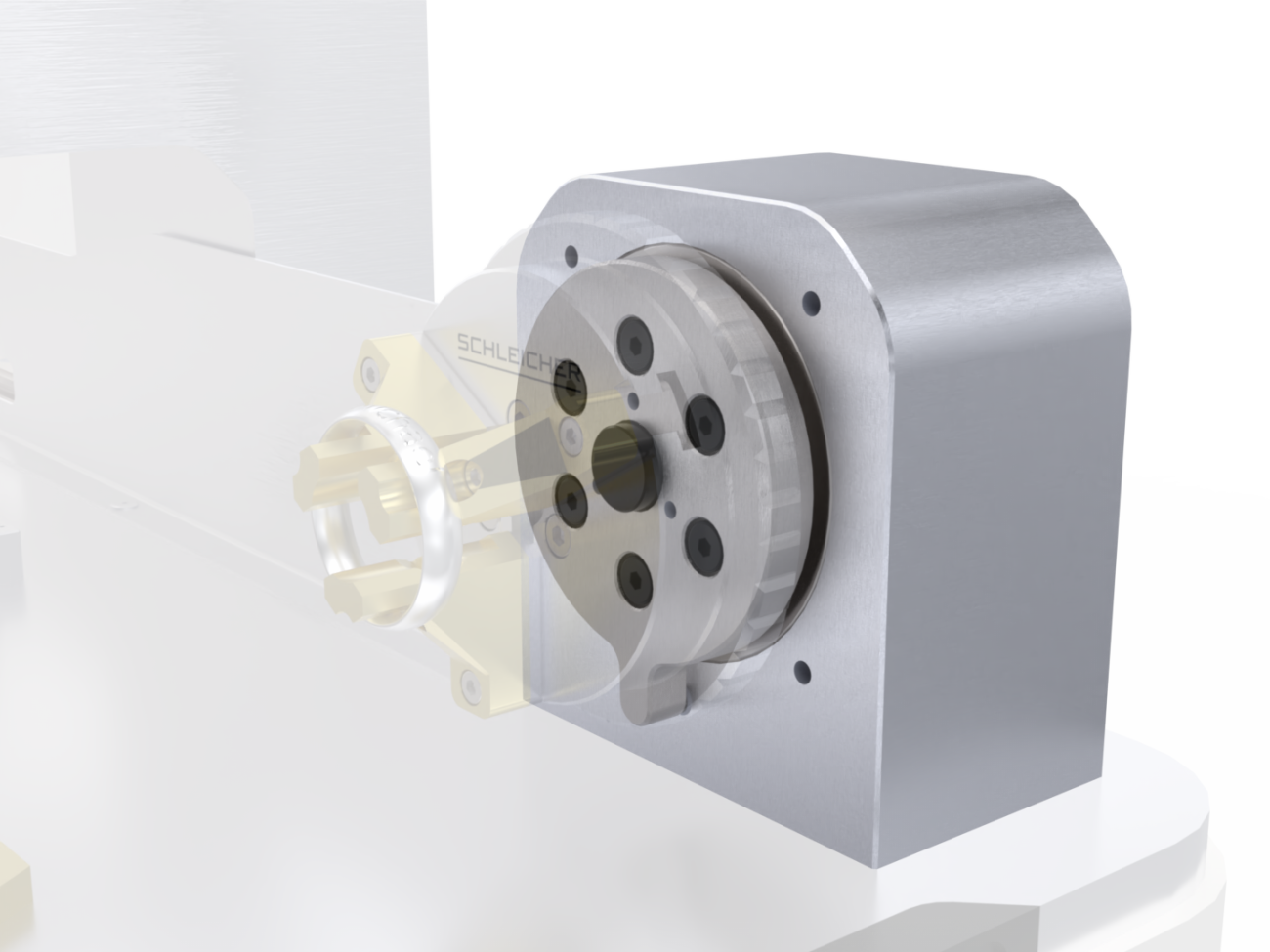

Precision rotation axis

High structural stability

The Enamill™ jewelry milling machine is equipped with backlash-free and stable guides. The guides are directly connected to the machine's solid base supports. We deliberately use profile rail guides, which guarantee significantly higher precision and stability than the shaft guides used in standard engraving machines. Shaft guides bend under load! In this way, we achieve maximum rigidity and precision. This has a direct effect on the quality of your products. The axis drives of the Enamill™ engraving machine are designed with preloaded ball screws. This allows us to achieve absolute zero backlash, longer tool life and more precise milling operations.

High-precision engraving and milling spindle

The CNC engraving machine is equipped with a high-performance milling spindle. This enables high cutting speeds and feed rates. Speeds up to 24,000 rpm can be achieved as standard. The engraving and milling times are significantly reduced. High cutting speeds are guaranteed even with small tools. As this depends on the tool diameter, the speed must necessarily be significantly higher for small tools. Commercially available engraving machines with speeds of less than 20,000 rpm are not enough here! Our CNC milling machines guarantee high and optimum speed ranges. Not fixed, but variably adjustable! The tools are always clamped centrally via a collet chuck in the milling spindle. This guarantees a long tool life thanks to optimum concentricity. Do you want even higher speeds? No problem! A milling spindle with up to 50,000 rpm is also available as an option.

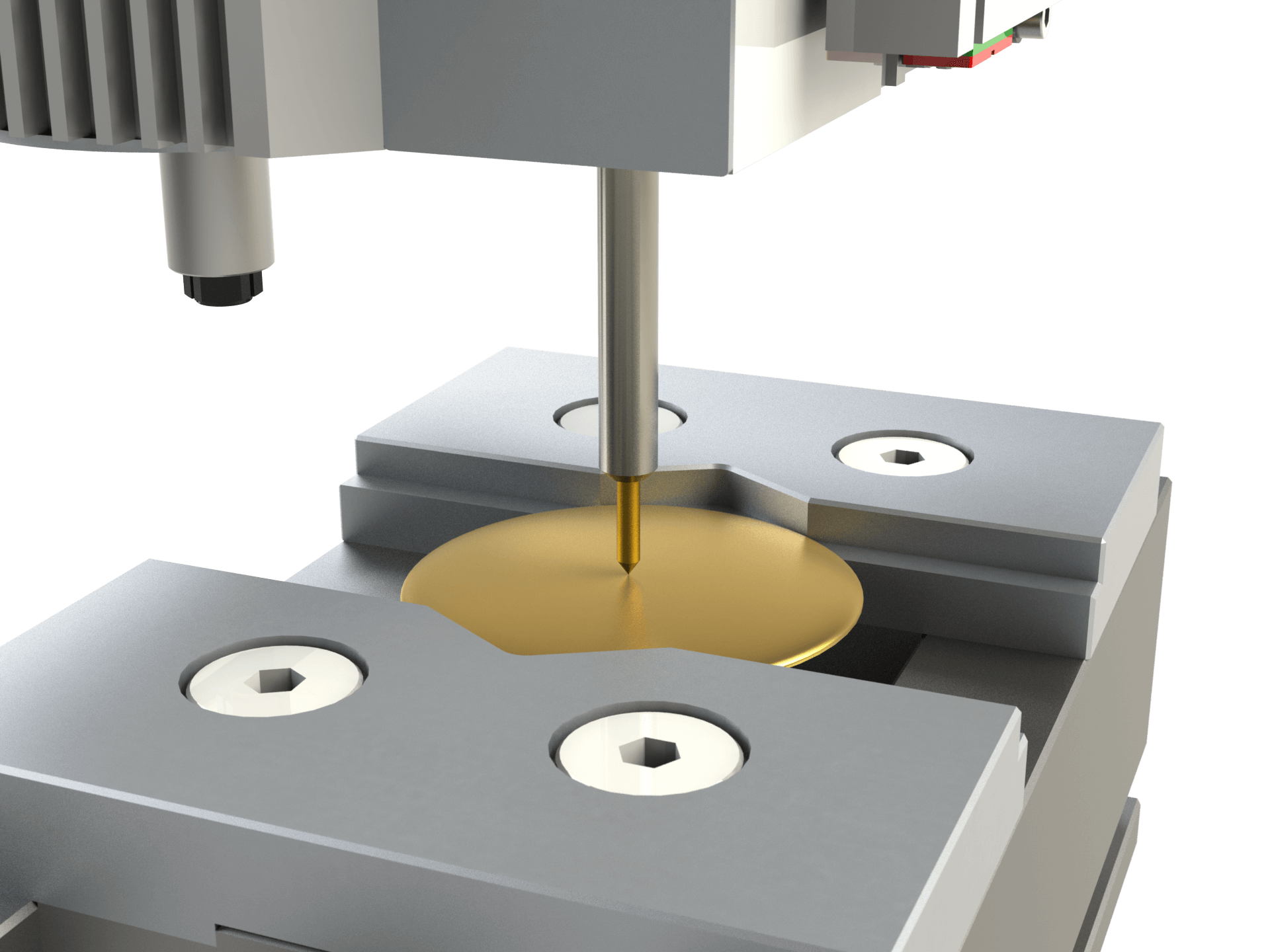

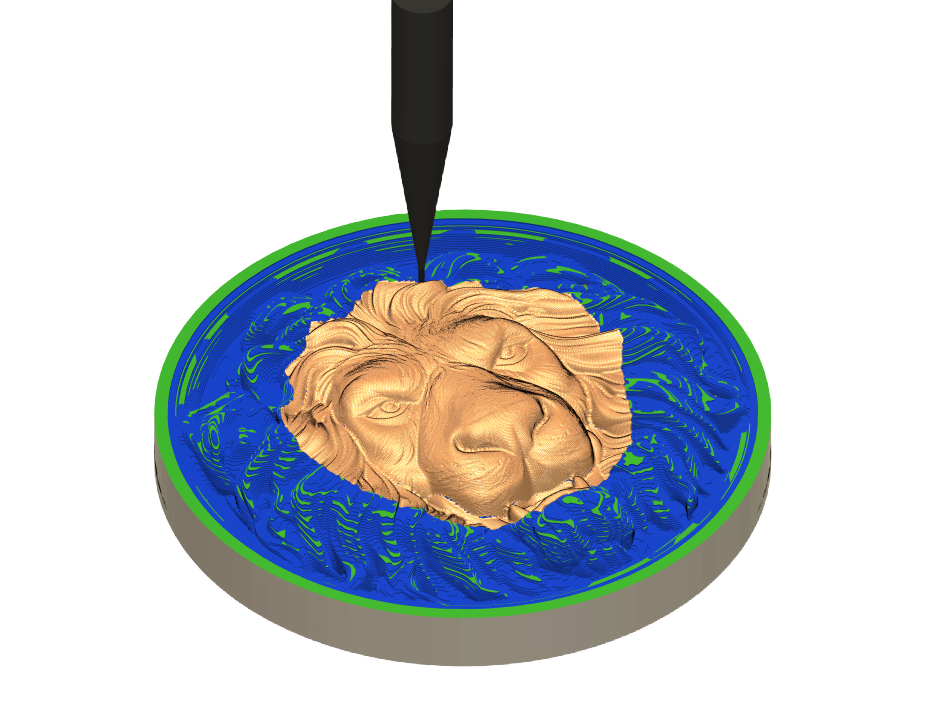

Measuring system for curved surfaces

The measuring system we have developed and patented in the CNC engraving machine is unique. Even curved jewelry surfaces can be measured with this system. The measurement data obtained is used to compensate for the height profile of the workpieces. Thus, even curved jewelry pieces (3D) can be engraved or milled optimally and quickly with simple and two-dimensional drawings. The touch probe can be flexibly switched on and off depending on whether it is needed for the current machining process. Gain an advantage over conventional engraving depth controllers, where the engraving depth must be set manually. In addition, you can reduce your tool wear enormously through the electronic height compensation.This is due to the use of optimum cutting data and the accessibility of the tool tip for coolant and lubricant.

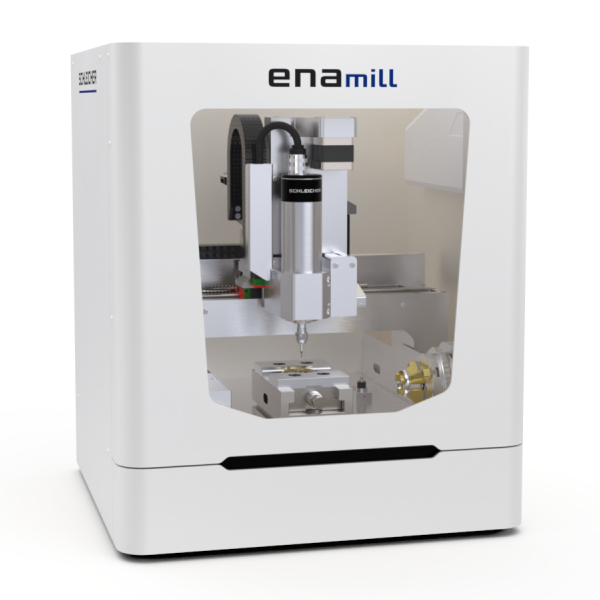

Innovative machine housing

The Enamill™ engraving machine for jewelry has a modern and aesthetic housing design. All components are permanently protected from dust and dirt. The chips and precious metals produced during machining remain 100% in the machine and can be removed easily and quickly. The machine door is designed as a front-lift door and opens upwards. This means that the door is never in the way, even if you are directly in front of the CNC machine. Loading the machine with your jewelry and workpieces is very easy from the front. The inside of the machine is optimally illuminated by powerful RGBW LED strips. The color of the lighting can be set individually. The already very quiet CNC milling machine is virtually noiseless thanks to the housing. This guarantees optimum integration in workshops and salesrooms.

Automatic measuring functions

This function allows you to set up and measure different tool lengths automatically. In addition, a further sensor for detecting the workpiece and material height is integrated on the machine's Z-slide. Both functions relieve you of the task of setting up the milling machine for jewelry, allowing you to concentrate fully on your engraving results.

Precise rotation axis for rotary engraving

The Enamill™ is equipped with a high-performance rotary axis for circular engraving. This guarantees sufficient torque reserves even with heavy machining. Thanks to the backlash-free Harmonic Drive gearbox, the rotary axis has no backlash and is absolutely repeatable. The CNC engraving machine guarantees the highest quality for your round engravings and products.

Complex milling or 3D engraving

Whether simple engravings, complex milling or 3D engravings. The Enamill™ offers you sufficient flexibility, stability and potential for various machining tasks. All axes of the CNC milling machine are controlled precisely and simultaneously. Depending on the machine variant, either 3- or 4-axis simultaneous milling.

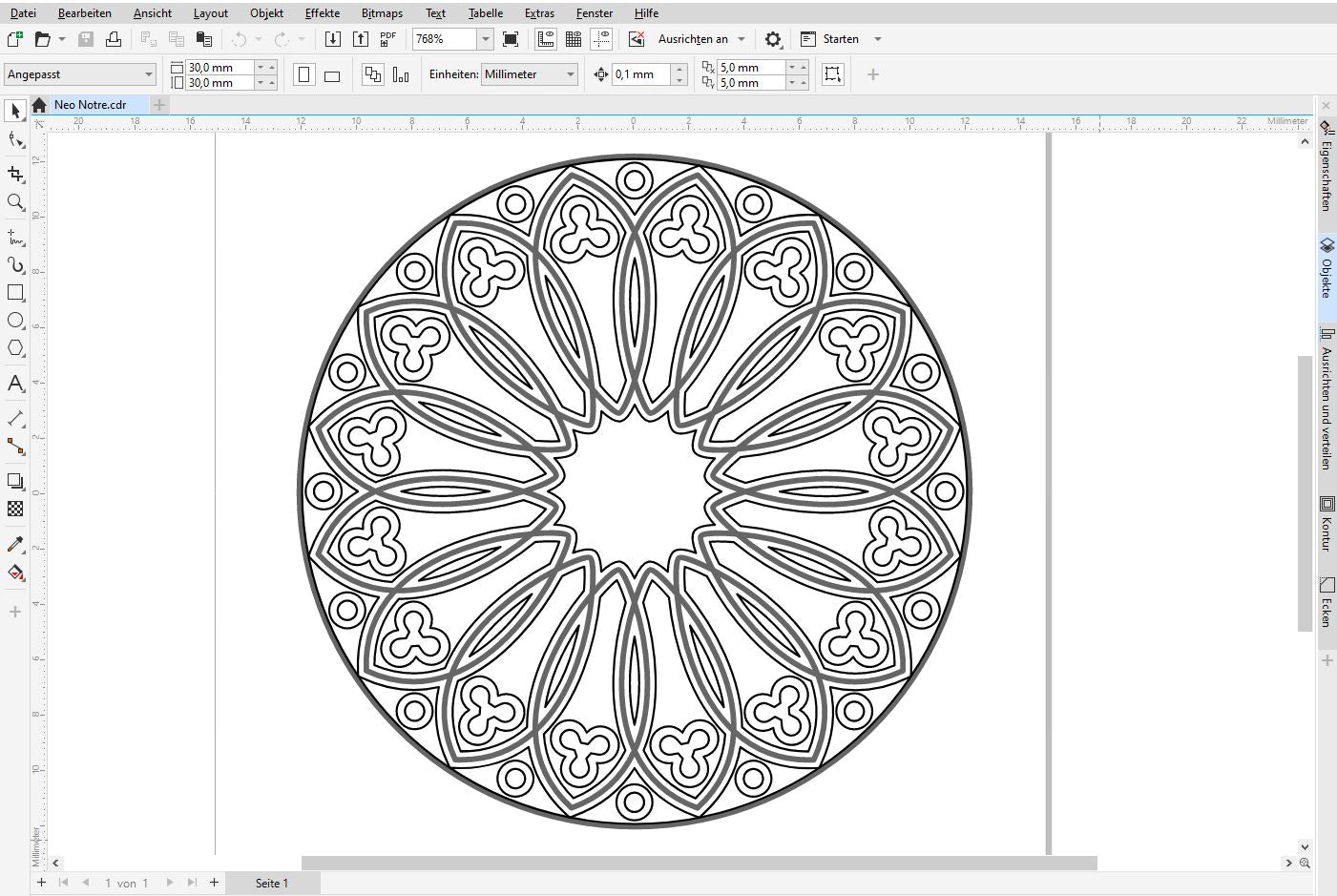

User-friendly software

The GraversPro™ software specially developed for our CNC machines makes brilliant engraving quick and easy.Whether engraving, cutting or milling. The software enables you to perform all types of machining such as internal ring engraving, external ring engraving and flat engraving. It doesn't matter whether you want to create simple or complex engravings. GraversPro™ always guarantees professional work thanks to advanced functions such as retracting and extracting, tool changing, drilling and travel direction settings.

Of course, you can also use the ENAMILL with other CAM software such as Autodesk Fusion 360. The CNC controls of our machines are flexible and can work with all common CAD/CAM systems.

Jewelry produced with the Milling Machine for jewelry

Our customers produce these pieces of jewellery on the Enamill™

Applications of the engraving centre

ENAMILL

Further information and links to the engraving center, jewelry engraving machine and milling machine for jewelry.