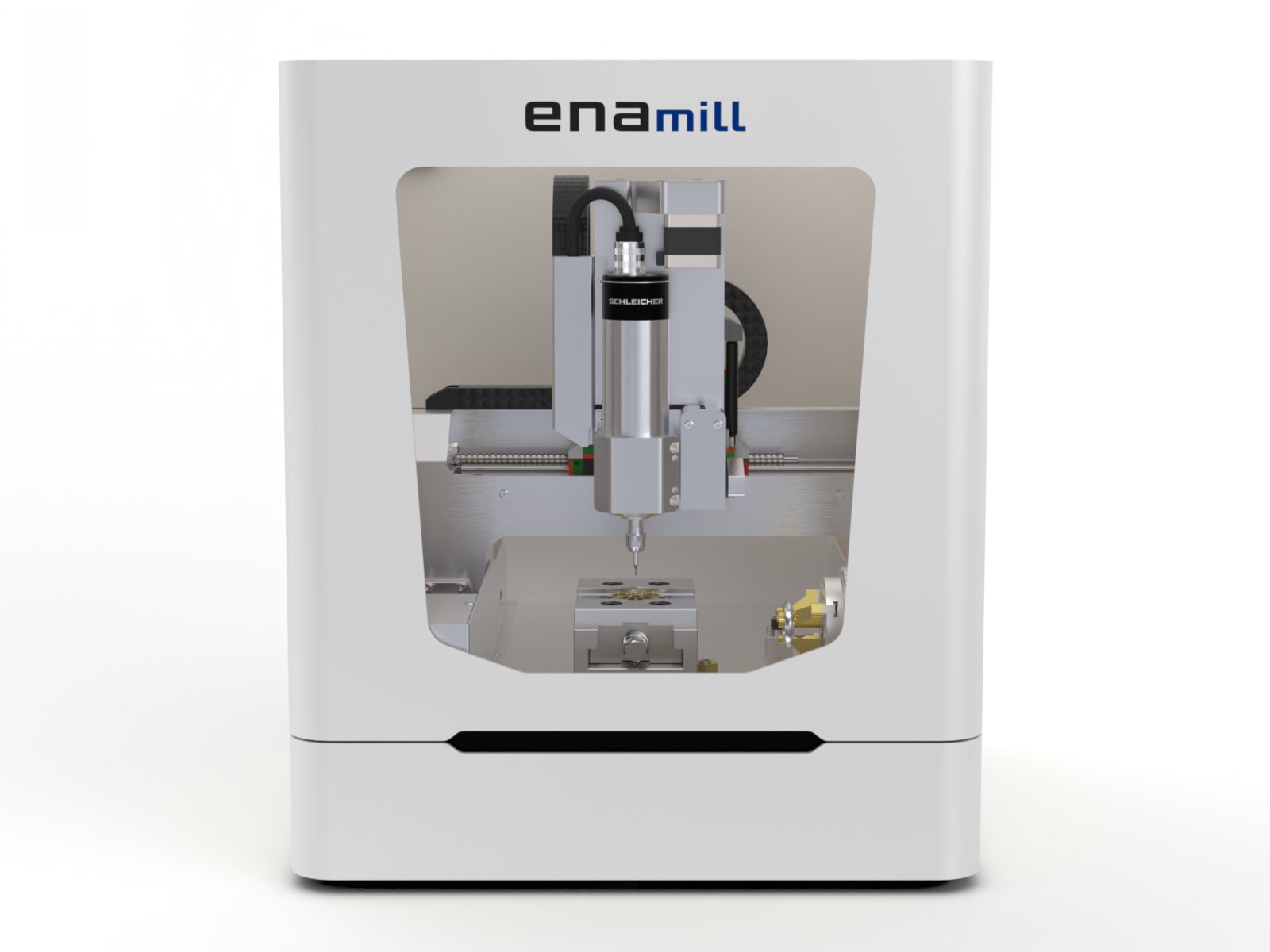

Benefits of our CNC machines

Our engraving machines, CNC milling machines and small machining centers for jewelry, prototypes and micromachining offer you significant advantages.

Higher surface quality and shorter process times with the CNC engraving machines

Especially for high machining depths and engravings, which are intended for the lifetime, our engraving machines offers you significantly shorter process times compared to laser machining. The chip volume or material removal per pass is significantly higher here and the process time is reduced accordingly. At the same time, with our engraving and milling machines, you achieve the highest surface qualities, which do not need to be reworked.

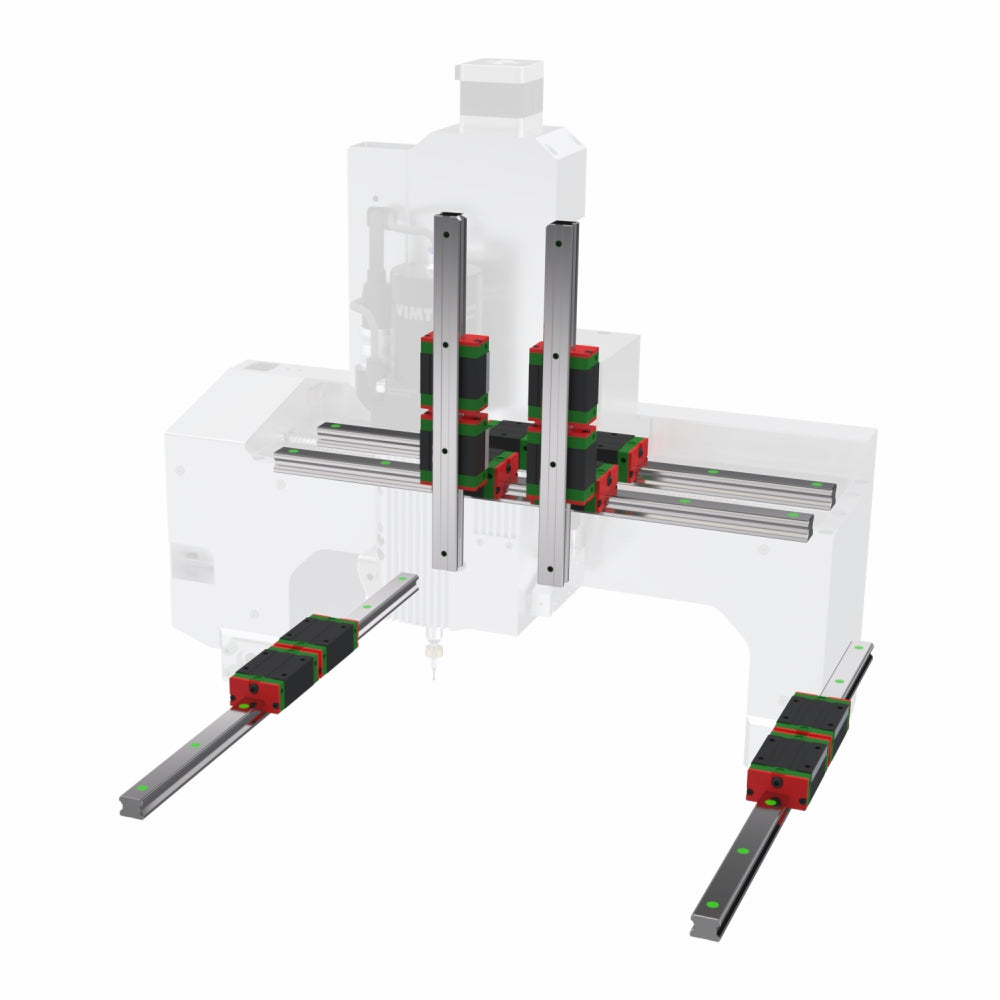

Innovative machine design leads to increased stability and rigidity

The unique machine design of the engraving machines results in significantly higher rigidity. Only through the increased stability can machining operations with significantly larger chip volumes be performed. Our milling machines can therefore be used not only for simple engraving work but also for more complex milling with larger tools. This offers you increased flexibility and shorter process times. You achieve better surface qualities and longer tool life due to the rigidity.

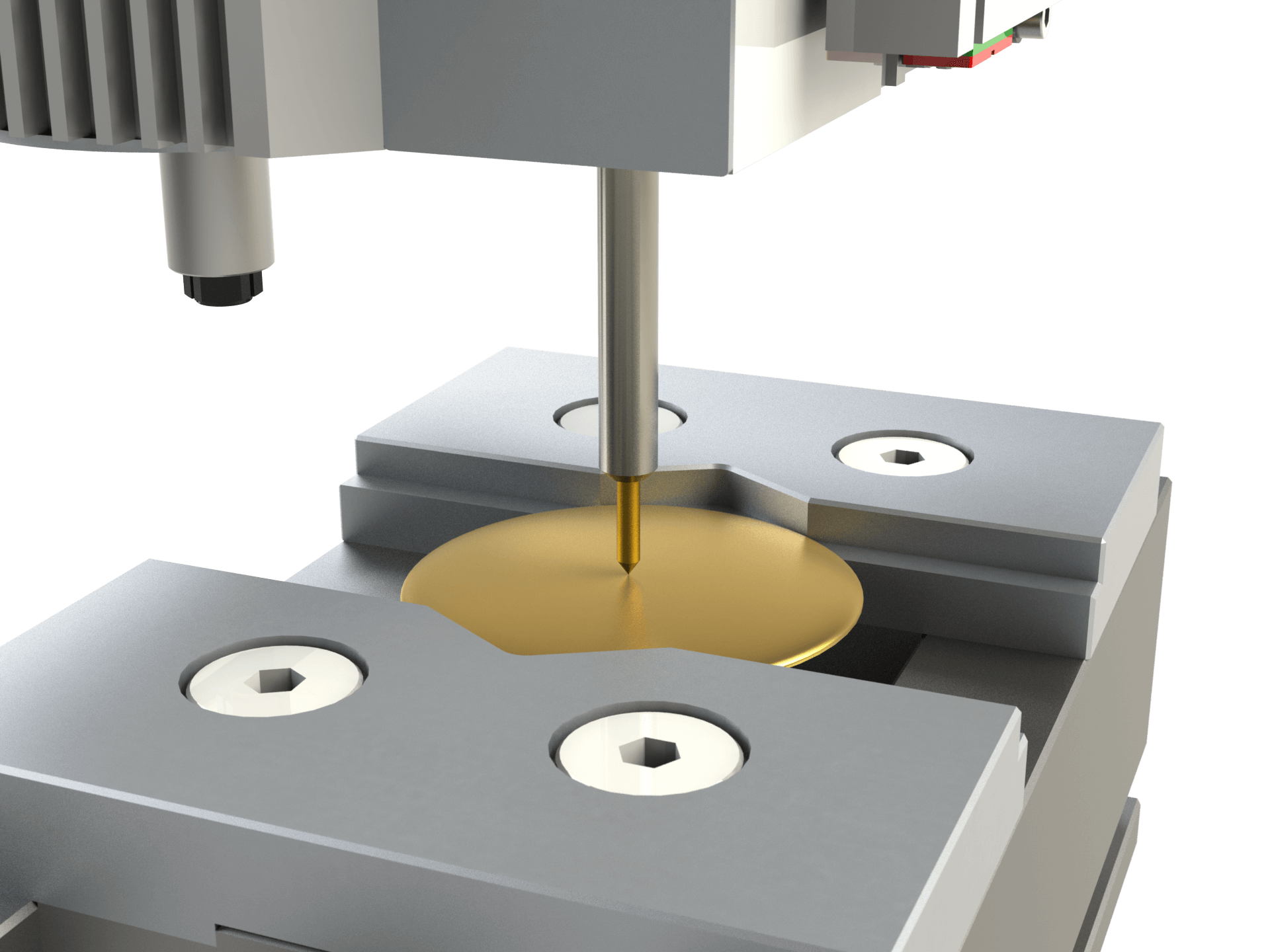

Better tool life due to minimum quantity lubrication in the milling machine

The Veromill™ milling machine has an integrated minimum quantity lubrication. This permanently cools the tool and lubricates the cutting process. The MQL brings the advantages of increased tool life and surface finishes to your workpieces.

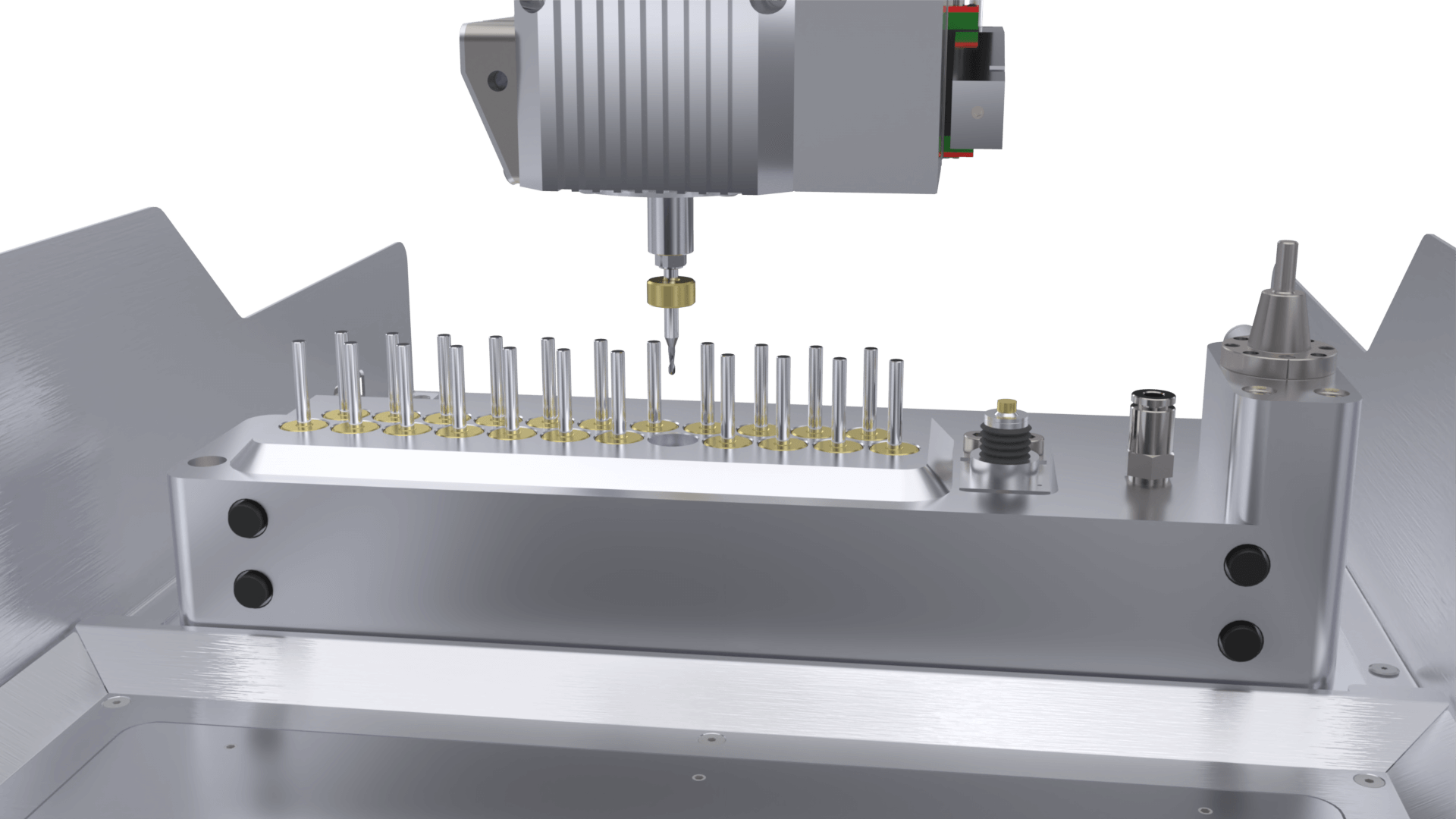

Automatic tool change during machining

Our Veromill™ has an automatic tool change. This allows you to easily store up to 23 machining tools in the tool magazine. If you need another tool during machining, the compact machining center automatically changes the tool and continues machining. In addition, the various tool lengths are automatically measured and corrected. Thus, even complex milling or engraving operations are possible in one piece and without manual intervention.

Patented electronic height correction for curved or uneven workpieces

With Schleicher Technic CNC machines for jewelry, the problems of mechanical engraving depth regulators are a thing of the past. Because here uneven workpiece surfaces are compensated electronically. The cutting depth and engraving depth can be set in the software depending on the material and application. The CNC engraving machines takes into account the maximum allowed cutting depth of the tool and moves step by step to the desired engraving depth. Only in this way can optimum cutting data be run, which leads to better workpiece qualities, process times and tool life.

Conventional mechanical engraving depth controllers:

The concept of an engraving depth regulator is based on spring preload and counterforce sleeve. The tip of the engraving tool protrudes from the counterforce sleeve with the size of the engraving depth. The sleeve sits on the engraving object and permanently grazes the workpiece surface during machining. Chips can get between the counterforce sleeve and the workpiece and scratch the usually very sensitive surfaces. In addition, the engraving depth must always be set manually. Another problem with depth controls is that only one engraving or cutting depth can be used during engraving. If the engraving depth does not correspond to the allowed cutting depth of the tool, the engraving depth regulator must be readjusted after each cutting plane. In most cases, the engraving depth does not correspond to the allowed cutting depth of the tool.